Choosing the wrong wood for a toy can lead to splinters and safety hazards. This can damage your brand's reputation and result in costly recalls, turning a great idea into a liability.

The best woods for toys are hard, non-splintering, and non-toxic hardwoods[^1] like Maple, Beech, and Birch. These woods are durable, have a smooth finish, and can withstand rough play, ensuring the final product is both beautiful and safe for children.

I've spent my career in manufacturing, mostly with molds and plastics. But the core principles are always the same, whether you're injecting plastic or carving wood. It all comes down to choosing the right material for the job. I've worked with partners like Woddlon on specialized projects, and I've seen firsthand how material choice makes or breaks a product, especially one for kids. You need to think about safety, durability, and how the material behaves during mass production[^2]. Let's walk through how I approach this, so you can make the right call for your next project.

All softwoods are unsafe for making children's toys.False

While many softwoods like pine can dent and splinter easily, some, like Poplar, are soft but have a uniform texture and are considered safe when properly finished. The key is hardness and splinter resistance, not just the 'softwood' or 'hardwood' category.

Maple wood is one of the hardest domestic woods, making it extremely durable for toys.True

With a Janka hardness rating of around 1,450 lbf, Hard Maple is exceptionally resistant to dents and wear, which is why it's a top choice for items like wooden blocks, cars, and other toys that see heavy use.

How Do You Choose the Best Wood for a Custom Wooden Toy?

Designing a one-of-a-kind custom toy is exciting, but your material choice is critical. A poor choice can undermine a great design, leading to a product that breaks or feels cheap.

For a custom toy, you must prioritize safety and durability above all else. The best wood is a dense hardwood that won't splinter, is naturally non-toxic, and can be sanded to a very smooth finish. Maple and Beech are my go-to recommendations for these reasons.

When a client comes to me with a unique toy design, we break down the wood selection process into three key areas. It’s not just about what looks good; it’s about what performs best and keeps kids safe. I remember a project for a set of custom alphabet blocks. The client was leaning towards a cheaper wood to save on initial costs. I showed them a sample of that wood next to a piece of hard maple. The difference in weight, feel, and finish was obvious. We discussed how the maple would resist dents from being thrown and wouldn't risk splintering. They agreed to the maple, and the final product was a huge success that passed every safety certification[^3] with ease.

Key Factors for Custom Toys

Here’s how we evaluate the options:

- Safety: The wood must be non-toxic. Avoid woods that can cause allergic reactions or contain natural toxins. It also needs to be splinter-resistant. A child's safety is the number one priority.

- Durability: Custom toys are often cherished for years. The wood should be hard enough to resist dents, scratches, and breakage from drops and rough play. This is where the Janka hardness scale[^4] is a useful guide.

- Finish and Feel: The wood should sand to a silky-smooth finish to be safe for little hands. The grain pattern and color also contribute to the toy's final look and feel, which is a big part of a custom product's appeal.

Here is a simple table to compare some common choices:

| Wood Type | Safety (Splinter Risk) | Durability (Janka Hardness) | Finish Quality | Best For |

|---|---|---|---|---|

| Maple | Very Low | High (1450 lbf) | Excellent | Blocks, cars, teething toys, puzzles |

| Beech | Very Low | High (1300 lbf) | Excellent | Building blocks, figures, rattles |

| Birch | Low | Medium (1260 lbf) | Very Good | Puzzles, smaller painted toys |

| Pine | High | Low (380 lbf) | Fair | Not recommended for unpainted toys |

| Oak | Medium (Porous) | High (1360 lbf) | Good | Not ideal due to large, open pores |

Oak is a great choice for toys because it is a hardwood.False

Although Oak is very hard and durable, its large, open grain (pores) can trap dirt and bacteria, making it less ideal for toys that children might put in their mouths. Woods with a closed, tight grain like Maple are more hygienic.

Beech wood is naturally anti-bacterial.True

Studies have shown that wood, including Beech, has natural antimicrobial properties that can kill bacteria on its surface, making it an excellent and hygienic choice for children's toys.

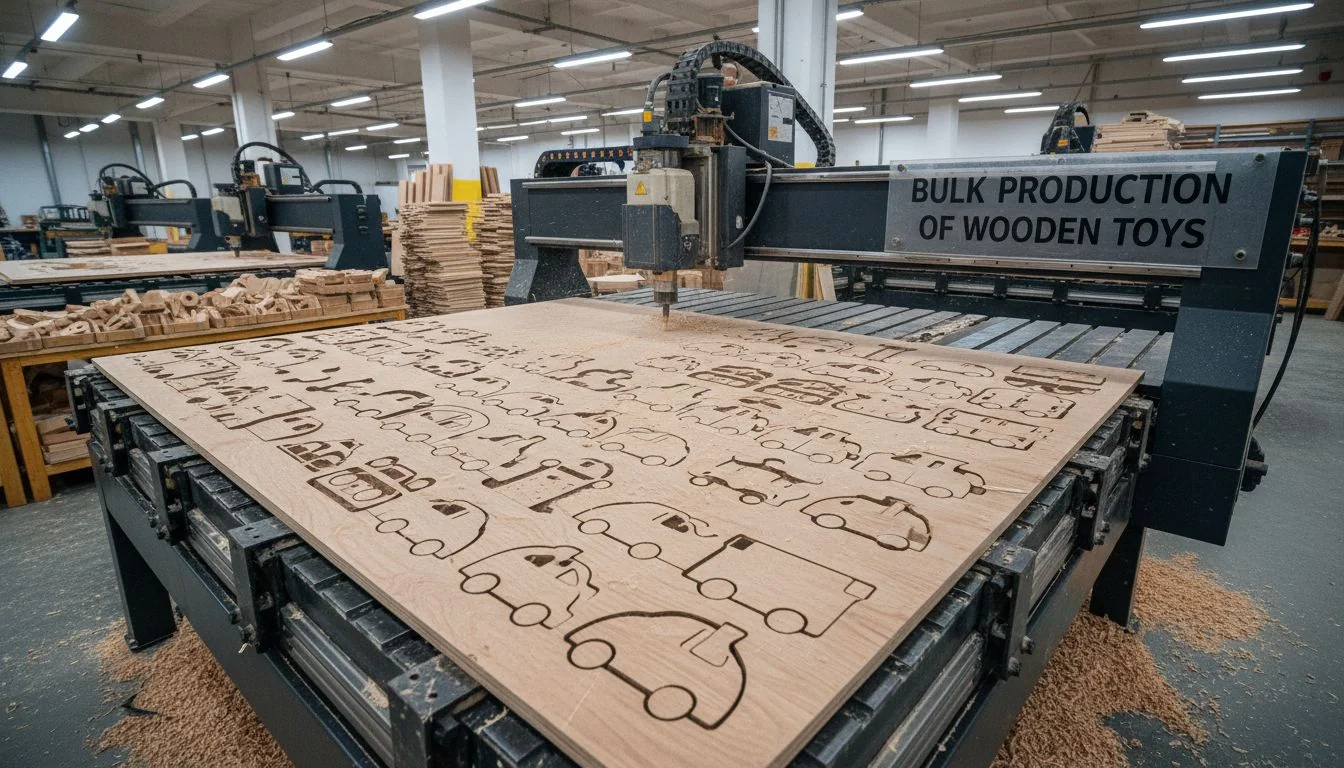

How Do You Choose Wood for Bulk Production?

Moving from a single prototype to thousands of units changes everything. Suddenly, cost, consistency, and machinability become just as important as the wood's physical properties. You need a strategy.

For bulk production, you need a wood that is not only safe and durable but also readily available, cost-effective, and easy to machine. This balance ensures you can scale up production without sacrificing quality or breaking the budget. Birch and Beech often hit this sweet spot.

When you're making thousands of something, small details create big problems. As a product designer like Jacky knows, optimizing for large-scale production is a different game. You can't just pick the fanciest wood. You have to think like a factory manager. Is the wood available in the quantities I need, year-round? Is the quality consistent from one batch to the next? How quickly will this wood wear down my CNC bits and other tools? Answering these questions is crucial. For mass-market toys, I often see manufacturers use Birch. It's a fantastic compromise. It's hard enough, finishes well, is more affordable than Maple, and is widely available from sustainable sources.

Balancing Cost, Supply, and Machinability

Here’s how to think about wood for mass production:

- Cost and Availability: You need a wood that fits your budget and can be sourced reliably in large volumes. Look for woods with stable supply chains. FSC or PEFC certification is also a major plus for marketability.

- Consistency: The material must be uniform. You can't have significant variations in color, grain, or density from one shipment to the next, as this will affect the final product's look and the manufacturing process.

- Machinability: How does the wood behave with industrial tools? A good choice will cut cleanly, require minimal sanding, and won't cause excessive wear on blades and bits. This directly impacts production speed and cost.

This table breaks down the manufacturing considerations:

| Wood Type | Approx. Cost | Global Availability | Machinability (CNC) | Best For Mass Production? |

|---|---|---|---|---|

| Maple | High | Good | Excellent | Yes, for premium/high-end toys. |

| Beech | Medium-High | Excellent (Europe) | Excellent | Yes, a great all-around choice. |

| Birch | Medium | Excellent | Very Good | Yes, excellent balance of cost/quality. |

| Poplar | Low | Good (N. America) | Good | Good for painted toys; dents easily. |

| Rubberwood | Low | Good (Asia) | Good | Yes, a very common eco-friendly option. |

Rubberwood is a poor-quality wood from old tires.False

Rubberwood is a high-quality, eco-friendly hardwood. It is harvested from rubber trees that have finished their latex-producing cycle, making it a sustainable byproduct of the rubber industry. It is not related to rubber tires.

Using Birch plywood is a good cost-saving method for flat toys like puzzles.True

High-quality Baltic Birch plywood is strong, stable, and less expensive than solid hardwood. It's perfect for items like puzzles and play sets, as it resists warping and can be cut precisely with lasers or CNC machines.

Conclusion

Choosing the right wood is key to a successful toy. For custom pieces, prioritize safety and feel with Maple or Beech. For bulk production, balance cost and machinability with Birch or Rubberwood.

References

[^1]: Explore the importance of non-toxic hardwoods in ensuring children's safety and health.

[^2]: Discover the key considerations for scaling up production while maintaining quality.

[^3]: Learn about safety certifications to ensure your wooden toys meet industry standards.

[^4]: Understanding the Janka hardness scale is crucial for selecting durable woods for children's toys.