Struggling to connect your beautiful toy designs with the right manufacturing process? Choosing the wrong one can lead to high costs and poor quality, jeopardizing your entire project.

High-quality wooden toy manufacturing[^1] relies on a series of precise processes. These include punching for simple shapes, drilling for holes, jigsaw cutting for curves, milling for profiles, and CNC engraving for details. Each step is crucial for achieving the final design with accuracy and efficiency.

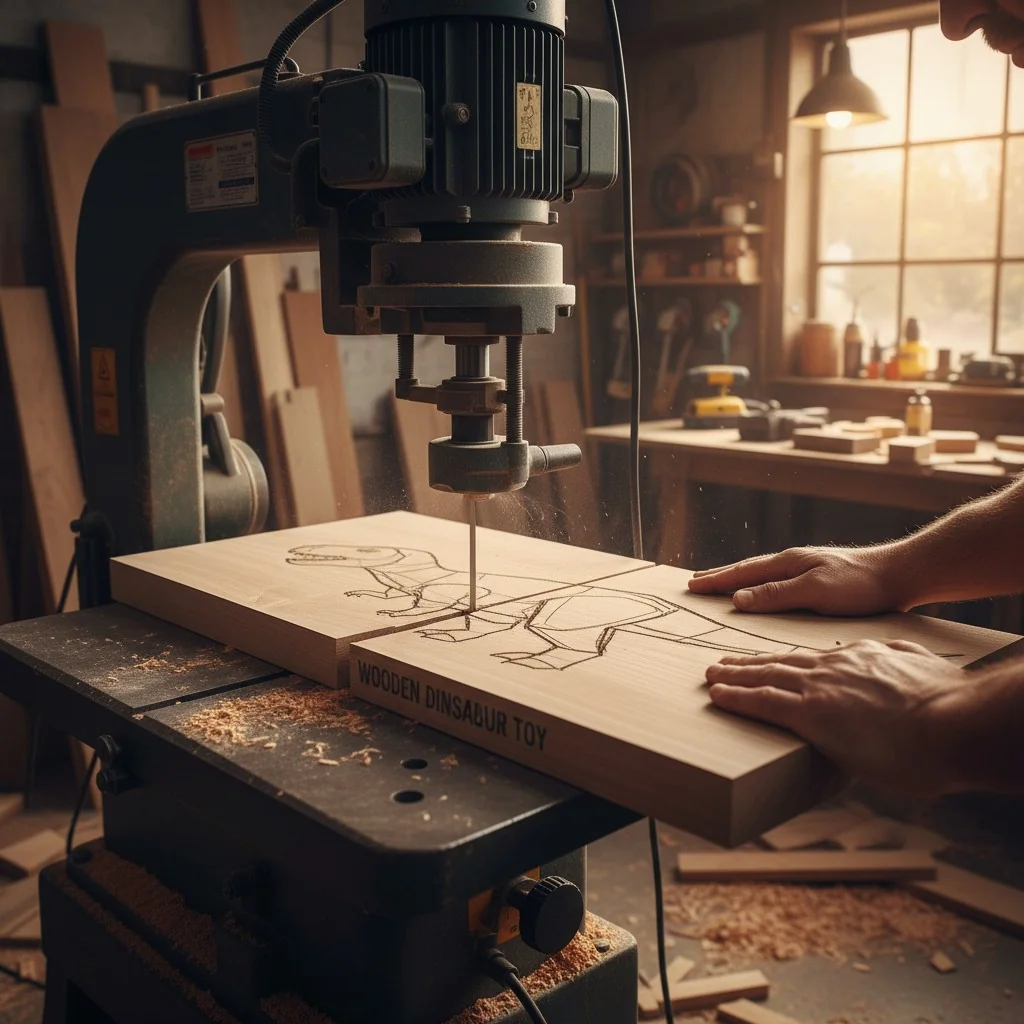

You've designed a fantastic wooden toy, but how does it go from a digital file to a physical product in a child's hands? The journey involves several key steps. In my years running a mold and CNC company, I've learned that success lies in mastering each stage. As a leading wooden toy manufacturer in China, we've refined these processes to an art. Understanding them will help you, as a designer, optimize your creations for efficient, high-quality production. Let's dive into the details of each technique we use every day.

The global wooden toy market is projected to reach $25.78 billion by 2028.सत्य

The market is growing due to increased demand for sustainable and durable toys, indicating a strong industry for high-quality manufacturing.

All wooden toys can be made using a single manufacturing process.असत्य

Complex toys require a combination of processes; for example, a toy car needs its body shaped (milling), wheels cut (punching), and axles fitted (drilling).

How Does Punching Shape Simple Wooden Toy Parts?

Need to create thousands of identical wooden wheels or blocks quickly? Manual cutting is too slow and inconsistent for mass production. We use punching[^2] to stamp out perfect shapes every time.

Punching, also known as die-cutting, uses a sharp steel die to press through thin wooden sheets. This method is incredibly fast and cost-effective for mass-producing simple components like wheels, small blocks, or flat puzzle pieces with high consistency. It is the best choice for high-volume parts.

Punching is all about speed and repetition. Think of it like a cookie cutter for wood. We design a custom steel-rule die in the exact shape of the part you need. This die is then mounted in a powerful press. We feed thin sheets of wood, usually plywood or MDF up to a few millimeters thick, into the machine. The press comes down with immense force, and in a single motion, it "punches" the shape out of the sheet.

How Punching Works

The process is simple but requires precision engineering. The die must be incredibly sharp to ensure a clean cut without splintering the wood. The pressure of the press has to be perfectly calibrated for the material's thickness and density. In our factory, we have dedicated punching lines that can produce thousands of parts, like toy car wheels or small geometric shapes, every hour. The key is the die design, which I've spent years perfecting to ensure clean cuts and long tool life.

Best Applications for Punching

This method is ideal for 2D parts with simple geometry. It's not suitable for complex curves or 3D shapes.

- Wheels and discs

- Simple puzzle pieces

- Small, flat geometric blocks

- Thin decorative elements

Punching is the fastest method for producing simple wooden shapes.सत्य

A mechanical press can perform hundreds of strokes per minute, making die-cutting significantly faster than any CNC or manual cutting method for high-volume, simple parts.

Punching can be used on thick blocks of hardwood.असत्य

Punching is only effective on thin materials, typically under 6mm, like plywood or MDF. Thick hardwood would break the die and result in a poor-quality, fractured cut.

What Makes Drilling a Critical Step in Wooden Toy Assembly?

Your toy design has parts that need to connect with axles or screws. Misaligned holes can ruin the entire assembly. We ensure perfect alignment with our precision drilling techniques[^3].

Drilling creates clean, precise holes for axles, dowels, screws, or strings. It is essential for any toy with moving parts or components that need to be joined. Using multi-spindle drill presses, we create multiple holes simultaneously, ensuring perfect alignment and high throughput.

Drilling might sound basic, but in toy manufacturing, it's a step where precision is everything. A hole that is off by even a fraction of a millimeter can mean a wheel that wobbles or a part that doesn't fit. This is why we move beyond simple hand drills for production.

The Importance of Precision

For any toy with moving parts, like a car with wheels or a pull-along animal, the axle holes must be perfectly parallel and perpendicular to the body. To achieve this, we use custom jigs and fixtures. These devices hold the wooden part in the exact same position every single time, guiding the drill bit to the precise location.

Types of Drilling Setups

For simple jobs, a single-spindle drill press is fine. But for efficiency, we rely on multi-spindle drill heads. These allow us to drill several holes at once. For example, when making a toy car body, we can drill both axle holes in a single operation. This not only saves time but also guarantees the holes are perfectly aligned with each other. I remember a project where a client's toy car wheels wobbled. The issue was a tiny angle in the drilled holes. We solved it by creating a new, more robust jig. That experience taught me that you can never over-invest in precision.

Using a brad-point drill bit prevents 'walking' and creates a cleaner entry hole in wood.सत्य

The center spur on a brad-point bit allows you to position it precisely, and the outer spurs score the wood fibers before the main cutting edge engages, resulting in a clean hole.

Drilling holes in wood always causes splintering on the exit side.असत्य

This is called 'tear-out.' It can be prevented by using a sharp bit, a slower feed rate, and placing a 'backer board' made of scrap wood firmly against the exit surface.

When is Jigsaw Cutting the Best Choice for Curved Shapes?

Your design features beautiful, organic curves that punching can't handle. How do you cut them without sacrificing quality? jigsaw cutting[^4] is the answer for those intricate, non-linear shapes.

Jigsaw cutting, often done with industrial scroll saws, is perfect for creating custom curves and internal cutouts in wooden toys. While slower than punching, it offers immense design freedom for shapes like animal figures, puzzle pieces, or decorative elements that require a handcrafted feel.

When you need to cut a shape that isn't a straight line or a simple circle, you need a different tool. This is where the jigsaw, or more accurately for industrial production, the scroll saw, comes in. This process allows us to cut almost any curve you can draw, giving life to animal shapes, wavy puzzle borders, and other organic forms.

The Art of the Curve

Unlike automated processes, scroll sawing is a hands-on skill. The machine uses a very fine, reciprocating blade that can turn on a dime. Our operators guide stacks of wood sheets through the blade, following a pattern traced on the top piece. This allows us to cut multiple identical parts at once, but it requires a steady hand and a deep understanding of how the blade interacts with the wood.

Balancing Speed and Detail

The choice of blade is critical. A wider blade can cut faster but can't make tight turns. A finer blade can navigate intricate details but cuts more slowly and is more fragile. We have to balance the complexity of your design with the need for efficient production. While machines provide the power, it's the skilled hands of our operators that create those smooth, flowing lines. We have a dedicated team who are true artisans in this craft, a key part of our strength as a manufacturer.

Scroll saws can make interior cuts without an entry point from the edge.सत्य

The blade can be detached, threaded through a drilled hole in the middle of the workpiece, and then re-secured, allowing for the cutting of internal shapes like the window of a toy house.

Jigsaw cutting is as fast as CNC routing for complex shapes.असत्य

Jigsaw/scroll saw cutting is a manual or semi-manual process that is significantly slower than a fully automated CNC router, which follows a digital path at high speed.

How Does Milling Create Complex 3D Shapes in Wood?

Flat shapes are not enough for your toy. You need rounded edges, grooves, and complex 3D contours. milling[^5] is the process that transforms simple blocks into sophisticated forms.

Milling uses rotating cutters to remove wood and shape a workpiece. It is essential for creating features like rounded edges, slots, and contoured surfaces. This process adds the tactile, safe, and high-quality finish that defines premium wooden toys, moving beyond simple 2D cutouts.

Milling is where a simple wooden cutout starts to feel like a finished toy. This process uses high-speed rotating blades, called cutters or bits, to shape the wood. It's how we get those soft, rounded edges that are safe for children and feel good to hold. It's also how we cut grooves for toy train tracks or slots for assembling parts.

From Block to Bespoke Shape

The most common milling tools in our workshop are wood shapers and routers. A router can be handheld for custom work or mounted in a table for more control. A shaper is a larger, more powerful stationary machine used for heavy-duty profiling. My background in CNC machining really informs how we approach milling. Even with manual shapers, the principles of cutter paths, speeds, and feeds are the same. We apply this engineering mindset to ensure every part is milled to exact specifications.

Key Milling Operations for Toys

Different cutter shapes create different profiles. This versatility is what makes milling so powerful.

| Operation | Description | Common Use in Toys |

|---|---|---|

| Edge Rounding | Creates a smooth, rounded edge using a "roundover" bit. | Making all toy parts safe and comfortable to hold. |

| Slotting | Cuts a narrow channel or groove with a "straight" bit. | Tracks for toy trains, slots for interlocking parts. |

| Profiling | Shapes the entire edge of a piece with a decorative bit. | Fancy edges on dollhouse furniture or toy castles. |

Rounding the edges of a wooden toy is a critical safety requirement.सत्य

International toy safety standards like ASTM F963 and EN-71 mandate that toys must not have sharp edges, making edge rounding (milling) a non-negotiable step for compliance.

Any type of wood can be milled at the same speed.असत्य

Hardwoods like maple require slower feed rates and more powerful machines than softwoods like pine to prevent burning the wood and to achieve a smooth finish.

Why is CNC Engraving the Ultimate Tool for Detail and Personalization?

Your toy needs a logo, a character's face, or intricate patterns. Hand-carving is too slow and inconsistent for production. CNC engraving[^6] delivers flawless detail on every single piece.

CNC (Computer Numerical Control) engraving uses a computer-controlled router to carve precise, detailed designs into the wood surface. It is perfect for adding logos, text, facial features, and complex patterns with perfect repeatability. This technology allows for mass customization and elevates the toy's value.

This is where modern technology meets traditional material. CNC engraving gives us incredible power to add fine details to your wooden toys. It bridges the gap between your digital design file and the physical product with unmatched precision.

Digital Precision on a Natural Material

The process starts with your CAD file. We use CAM software to translate that design into a set of instructions, called G-code, that the CNC machine can understand. The machine then moves a tiny, spinning cutting bit over the surface of the wood, carving away material with an accuracy of a fraction of a millimeter. This is how we can engrave a smiling face on a thousand little figures, and each one will be identical. This is where our strength as a modern manufacturer truly shines. Our bank of CNC machines runs 24/7, turning complex digital designs from clients like you into reality.

CNC vs. Laser Engraving

People often ask about the difference between CNC and laser engraving. A CNC machine uses a physical bit to carve and remove material, creating depth and a V-groove or ball-nose profile. A laser burns the surface of the wood, creating a darker, high-contrast mark with very little depth. We use both, but CNC engraving is often preferred for a more tactile, high-end feel.

CNC machines can achieve accuracies of less than 0.01 millimeters.सत्य

Modern industrial CNC routers have high-precision ball screws and servo motors that allow for positional accuracy measured in microns, ensuring perfect repeatability across thousands of parts.

CNC engraving is always the best method for adding graphics to wood.असत्य

For full-color graphics or very fine, non-recessed details, other methods like UV printing or screen printing are often more suitable and cost-effective than CNC engraving.

निष्कर्ष

Understanding these core processes—punching, drilling, jigsawing, milling, and CNC engraving—is key. It empowers you to design better, more manufacturable toys and choose the right production partner for your vision.

References

[^1]: Explore the best practices in wooden toy manufacturing to ensure quality and efficiency in production.

[^2]: Learn about the punching process and its efficiency in producing simple wooden shapes for toys.

[^3]: Learn about precision drilling techniques that ensure perfect alignment and high-quality assembly in toy manufacturing.

[^4]: Discover how jigsaw cutting is used to create intricate shapes in wooden toys, enhancing design possibilities.

[^5]: Understand the milling process and its importance in creating complex shapes and safe edges for wooden toys.

[^6]: Find out how CNC engraving adds detailed designs and personalization to wooden toys, elevating their value.