Want unique wood pieces but the process seems too complex? High costs and finding the right maker can stop a great idea. This guide simplifies everything for you.

To get custom wood pieces[^1], start with a detailed design, preferably a CAD file. For single items, find a local woodworker. For bulk orders, vet and partner with a specialized manufacturer, ensuring they can meet your quality and material specifications.

You have a brilliant idea for a wooden product, but turning that concept into a physical, high-quality item is the real challenge. It's easy to get lost in the details of design, materials, and finding a reliable partner who can actually make what you envision. The path from a digital file to a finished product can feel overwhelming, but it doesn't have to be. Let's break down the entire process, so you can move forward with confidence and bring your wooden creations to life.

Any type of wood is suitable for any custom project.False

Different woods have varied properties like hardness, grain, and moisture resistance. For example, soft pine is great for simple crafts, while hard oak is needed for durable furniture. The choice directly impacts the product's look, feel, and longevity.

A detailed technical drawing or CAD file is essential for accurate custom wood manufacturing.True

CAD files provide precise dimensions, tolerances, and specifications. This clarity minimizes errors, reduces back-and-forth communication, and ensures the final piece matches your exact design intent, which is critical for professional results.

How Can You Custom-Make Wood Pieces Effectively?

Your design is ready, but you're stuck on the practical steps of getting it made. Choosing the wrong process or material can lead to wasted time, money, and disappointment.

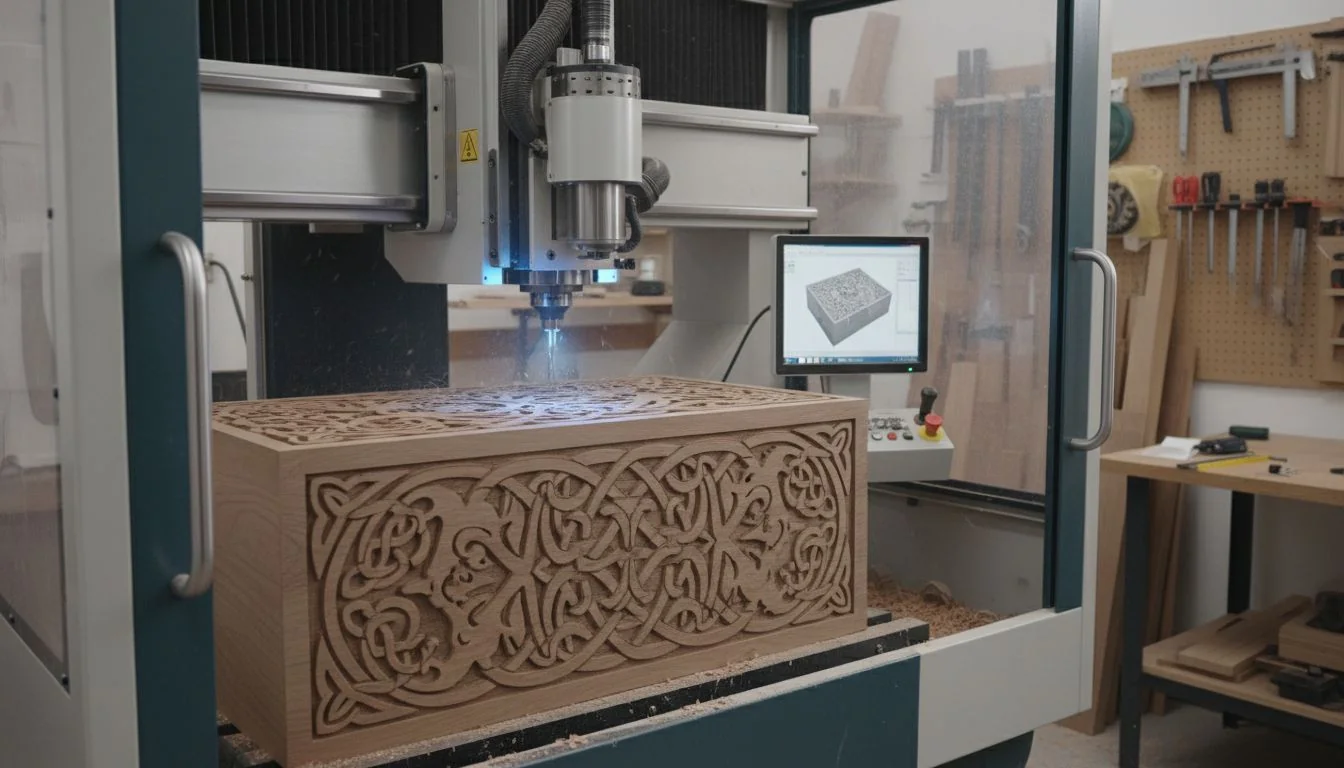

First, finalize your design with detailed specifications and choose the right wood. Next, select a manufacturing method like CNC machining[^2] for precision or traditional woodworking for an artisanal feel. Clear communication with your maker is essential.

Getting a custom wood piece made right the first time depends on how well you prepare. It's not just about having a good idea; it's about translating that idea into a clear, actionable plan for a manufacturer or craftsman. As someone who has managed countless manufacturing projects, I've learned that success is all in the details you provide upfront. A small oversight in the design file or a poor material choice can have big consequences down the line. Let's dive deeper into the key stages that ensure your custom wood project turns out exactly as you imagined, whether you're making one piece or one thousand.

Finalizing Your Design for Manufacturing

Before you approach anyone to make your piece, your design needs to be production-ready. For a professional like Jacky, this means going beyond a simple sketch. You need a detailed 3D CAD model and 2D technical drawings. Use standard file formats like STEP, IGES, or DXF. Your drawings must specify critical tolerances, the desired surface finish (e.g., sanded to a certain grit, varnished, or painted with a specific Pantone color), and any assembly instructions. This level of detail removes guesswork and protects you from errors.

Choosing the Right Wood

The type of wood you choose defines the final product's character, durability, and cost. You need to match the material to the application. A children's toy needs to be durable and non-toxic, while a decorative piece might prioritize a beautiful grain.

| wood type[^3] | Hardness | Best For | Cost |

|---|---|---|---|

| Pine | Soft | Inexpensive toys, simple furniture, prototypes | Low |

| Beech | Hard | Durable toys, kitchenware, chairs | Medium |

| Maple | Very Hard | Cutting boards, high-end toys, flooring | Medium-High |

| Oak | Hard | Premium furniture, cabinetry, flooring | High |

| Walnut | Hard | Decorative items, high-end furniture, veneers | High |

Selecting the Manufacturing Method

Your choice of manufacturing method[^4] depends on your design's complexity, the quantity you need, and your budget.

- CNC Machining: This is the best option for complex shapes, tight tolerances, and repeatable results. It's perfect for product designers who need precision parts that fit together perfectly.

- Laser Cutting/Engraving: Ideal for cutting intricate 2D shapes from wooden sheets or for adding detailed logos and patterns to a surface.

- Traditional Woodworking: For one-of-a-kind, artisanal pieces, a skilled craftsman using hand tools can achieve results that machines can't replicate. This is best for bespoke furniture or artistic objects.

CNC machining is always the best method for custom wood pieces.False

While precise, CNC isn't always cost-effective for simple, one-off projects where traditional methods might be faster and cheaper. The 'best' method depends on complexity, volume, and the desired artisanal finish.

The moisture content of wood significantly affects the final product's stability.True

Wood expands and contracts with humidity changes. Using properly kiln-dried wood is critical because it minimizes the risk of warping, cracking, or splitting after manufacturing, ensuring the product's long-term quality and integrity.

How Do You Custom-Order Bulk Wood Products From China?

You need to produce wooden items in bulk, but local manufacturing costs are just too high. Sourcing from overseas feels risky, with worries about quality, communication, and shipping logistics.

I'll share my experience on how to successfully partner with Chinese manufacturers. Find reputable suppliers on platforms like Alibaba, vet them thoroughly, get samples, and provide clear technical packs to ensure quality control[^5].

When I first started my trading company, I faced this exact problem. I had clients who designed amazing products, like handmade wooden toys, but producing them in Europe or North America at scale was financially impossible. The costs were just too high. This led me to explore manufacturing in China, and I quickly learned why so many famous brands already produce there. It's not just about lower costs; it's about accessing a massive, experienced manufacturing ecosystem. But navigating it requires a clear strategy. Let me walk you through how to do it right and avoid the common pitfalls.

Why China for Bulk Wood Production?

From my years in the industry, I can tell you the advantages are clear. The primary driver is cost-effectiveness. Labor and material costs are significantly lower, which is crucial for products that require manual work like sanding, painting, and assembly. This is why most popular wooden toys are produced in China. Beyond cost, China has an incredibly developed supply chain and infrastructure. There are entire regions, like Yunhe County, known as the "Wooden Toy City," that are dedicated to this craft. They have decades of experience, skilled labor, and the capacity to handle huge production volumes for major international brands.

The Sourcing and Vetting Process

Finding the right partner is the most critical step. Rushing this can lead to disaster. You need a methodical approach to vetting potential suppliers.

| Step | Action | My Key Tip |

|---|---|---|

| 1. Find Suppliers | Use B2B platforms like Alibaba or Made-in-China.com. Attending trade fairs like the Canton Fair is also effective. | Look for "Gold Suppliers" with 5+ years of experience. Read reviews carefully and filter for manufacturers, not trading companies. |

| 2. Initial Vetting | Request their company profile, business license, and quality certifications (e.g., ISO 9001, BSCI, FSC for wood). | Ask for photos and videos of their factory in action. A transparent and proud supplier will share these readily. Reluctance is a red flag. |

| 3. Request Samples | Always order a pre-production sample based on your exact design. This is a non-negotiable step. | Pay for the sample and the shipping. It's the best money you'll spend, as it's your ultimate quality check before committing to a large order. |

| 4. Factory Audit | For large or long-term orders, consider a third-party audit or a personal visit to verify their capabilities. | An audit confirms that the factory you saw in pictures is real and that they have the equipment and processes they claim. |

Managing Production and Quality Control

Once you've chosen a supplier, clear communication is everything.

- Use Simple Language: Keep your emails and instructions simple and direct. Use images and diagrams wherever possible to overcome language barriers.

- Provide a "Tech Pack": This is your manufacturing bible. It must include all CAD files, material specifications (e.g., "FSC-certified Beech wood"), Pantone color codes, safety requirements (e.g., EN-71 for toys), and detailed packaging instructions.

- Set Quality Checkpoints: Don't wait until the end to inspect. Agree on quality checks at key stages: after raw material cutting, before painting, and a final random inspection before shipping. This allows you to catch issues early.

Many well-known European and American wooden toy brands manufacture their products in China.True

Major brands like Hape, Melissa & Doug, and Brio have significant manufacturing operations or partnerships in China. They leverage the country's cost advantages and large-scale production capabilities, a fact widely acknowledged in the global toy industry.

The lowest price on Alibaba always represents the best deal for bulk orders.False

Extremely low prices are a major red flag. They often indicate compromises on material quality, unsafe labor practices, or a complete lack of quality control. The best deal balances a competitive price with a supplier's reputation, transparency, and sample quality.

Conclusion

Customizing wood pieces is very achievable. Start with a solid design, then find the right maker for single items or vet Chinese suppliers for cost-effective bulk production.

References

[^1]: Explore resources that guide you in creating unique custom wood pieces tailored to your needs.

[^2]: Discover the benefits of CNC machining for achieving precision in custom wood projects.

[^3]: Explore the characteristics of different wood types to choose the best one for your project.

[^4]: Understand the various manufacturing methods available for creating custom wood pieces.

[^5]: Learn effective strategies for maintaining quality control during the wood manufacturing process.