Sourcing custom bamboo products feels risky. Quality issues and communication barriers can derail your project. I'll show you how to navigate it like a pro and get it right.

The key to successful wholesale bamboo product manufacturing is a multi-step process. It involves finding a reliable Chinese manufacturer[^1], providing clear design sketches, understanding bulk production nuances, implementing strict quality control, and validating through sampling. This guide breaks down each step for you.

I've spent my entire career in the mold and CNC manufacturing world, helping designers just like you bring their ideas to life. The principles for making great products are the same, whether it's plastic or bamboo. It all comes down to having a solid process. Let's walk through that process together, starting with the most important step: finding the right partner.

Bamboo is technically a type of wood.False

Bamboo is a type of grass, not wood. This distinction is important as it affects its properties, such as its fast growth rate and unique grain structure, which influence manufacturing processes.

China produces over 80% of the world's bamboo products.True

China is the world's largest producer and exporter of bamboo, with a vast infrastructure and deep expertise in bamboo cultivation and processing, making it a primary hub for sourcing.

How Do You Find a Reliable Bamboo Products Wholesale Manufacturer in China?

Searching for a good manufacturer online is overwhelming. You worry about scams, poor quality, and language barriers. I'll give you a clear roadmap to find a trustworthy partner.

Start with online B2B platforms like Alibaba, but don't stop there. Vet them by checking business licenses, certifications (like FSC for bamboo), and factory audit reports. Ask for references and look for specialists in bamboo manufacturing, not just general trading companies.

Dive Deeper: Vetting Your Manufacturing Partner

Finding a supplier is easy; finding the right one is hard. I remember a client who almost lost thousands with a supplier who looked great on paper but was just a trading company with no real factory. We had to step in and find them a real specialist. Vetting is non-negotiable. You need to dig deeper than the front page of their website. A true manufacturing partner will have the technical expertise to not only make your product but also suggest improvements. At Moldle, our experienced technicians and sales engineers provide this kind of guidance, but you need to ensure your chosen factory has a similar mindset.

Key Vetting Steps

| Step | Action | Why It's Important |

|---|---|---|

| 1. Online Search | Use Alibaba, Made-in-China.com, and industry directories. | This is your starting point to create a long list of potential suppliers. |

| 2. Initial Screening | Check their company profile, years in business, and product focus. | Weed out general traders. You want a bamboo specialist for their material knowledge. |

| 3. Request Documents | Ask for their Business License, ISO 9001, and FSC certification[^2]. | This verifies they are a legitimate business and follow quality and sustainability standards. |

| 4. Communication Test | Evaluate their responsiveness, English proficiency, and technical understanding. | Good communication is key to avoiding misunderstandings during production. They must understand your design. |

All suppliers listed as 'Gold Supplier' on Alibaba have been physically audited.False

A 'Gold Supplier' status is a paid membership. While Alibaba does offer verification services, you must specifically look for suppliers who are 'Verified' and check their audit reports, not just the 'Gold' badge.

FSC (Forest Stewardship Council) certification is a key indicator of a responsible bamboo supplier.True

FSC certification ensures that the bamboo is sourced from responsibly managed forests, which is a critical factor for brands focused on sustainability and a major selling point for eco-conscious consumers.

Do Custom Bamboo Products Really Require Detailed Sketches from the Customer?

You have a great idea for a custom bamboo product. But you're unsure what level of detail the manufacturer needs. Vague instructions lead to costly mistakes and frustration.

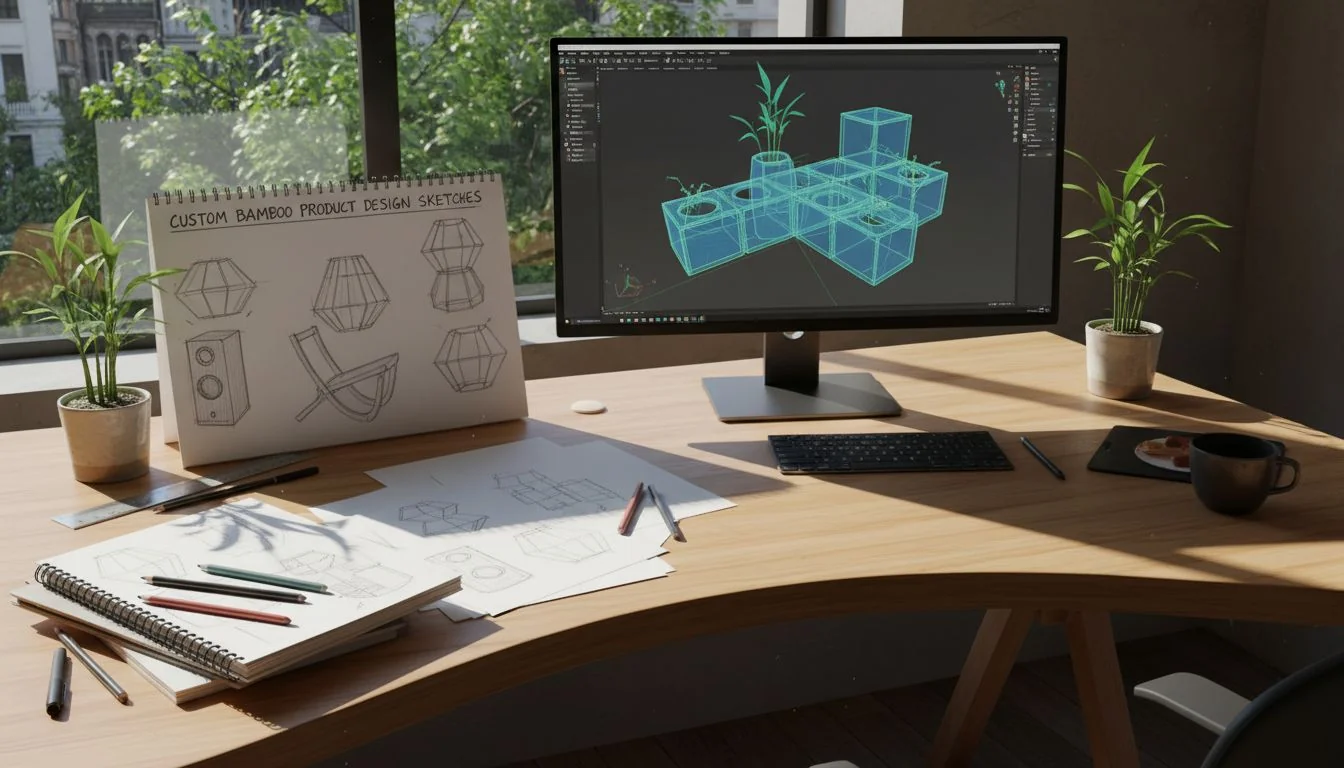

Yes, absolutely. To get exactly what you want, you must provide detailed 2D and 3D drawings. These sketches should include dimensions, tolerances, material specifications, surface finish requirements, and assembly instructions. This is your primary communication tool with the factory's engineer.

Dive Deeper: From Sketch to Reality

I've seen projects fail because of a single missing dimension on a drawing. As a designer, your CAD file is your contract with the factory. It must be perfect and leave no room for guessing. I always tell people to think of it as the blueprint for a house; you wouldn't let a builder start working from a rough napkin sketch, would you? The same applies here. The more detail you provide upfront, the smoother the process will be. A professional manufacturer will appreciate this level of detail because it makes their job easier and ensures they can deliver exactly what you're paying for. It shows you are a serious partner.

Essential Elements for Your Design Files

| Element | Description | Example |

|---|---|---|

| 3D Model | A file in a universal format like .STEP or .IGES. | This allows the manufacturer to see the product from all angles and use it for CNC programming. |

| 2D Drawings | Detailed blueprints with all critical information. | Include dimensions, geometric dimensioning and tolerancing (GD&T), and callouts for specific features. |

| Material Spec | Specify the type of bamboo (e.g., Moso) and any treatments. | "Natural Moso Bamboo, carbonized finish." |

| Finish Spec | Define the desired surface texture and coating. | "Sanded smooth to 220 grit, finished with food-safe mineral oil." |

A simple hand-drawn sketch is enough for a manufacturer to start production.False

For custom wholesale production, professional CAD drawings (2D and 3D) are required to ensure precision, consistency, and to avoid misinterpretation. Hand sketches are only for the initial idea stage.

Providing a .STEP file is a standard practice for sharing 3D models with manufacturers.True

.STEP is a neutral CAD format that can be opened by almost any CAD software, making it ideal for collaboration between designers and manufacturers who may use different systems.

What Should You Pay Attention to During Bulk Production?

Your sample was perfect, so you approved bulk production. Now you're worried if the quality will be consistent across thousands of units. This is a common and valid fear.

During bulk production, focus on consistency. Key areas are raw material consistency, machine calibration, and the "golden sample[^3]." Use the approved pre-production sample as the absolute benchmark for every unit that comes off the line. Regular communication is crucial.

Dive Deeper: Maintaining Quality at Scale

Scaling from one perfect sample to 10,000 units is the real test of a manufacturer. I always tell my clients to establish clear quality checkpoints throughout the process. Don't just wait until the end to inspect everything. Bamboo is a natural material, which means it has variations. A good factory knows how to manage this. They will have processes for sorting raw materials by color and grain to ensure the final products look uniform. You should ask them about these processes. This is where a true bamboo specialist shines compared to a general factory. They understand the material's unique challenges and have solutions ready.

Key Focus Areas for Bulk Production

| Area | Action | Why It's Important |

|---|---|---|

| Raw Material | Confirm the factory is using the same batch or supplier of bamboo as the sample. | Bamboo's color, grain, and density can vary, affecting the final product's look and feel. |

| Tooling & Jigs | Ensure that molds, cutting tools, and assembly jigs are maintained. | Worn-out tools can lead to dimensional inaccuracies and defects over a long production run. |

| First-Article Inspection | Inspect the first few pieces off the production line against the golden sample. | This catches any setup errors early before thousands of bad parts are made. |

| Production Monitoring | Ask for regular updates, photos, and even short videos from the factory floor. | This keeps you informed and shows the factory you are paying close attention to quality. |

Once a sample is approved, you don't need to monitor the bulk production process.False

Continuous monitoring is essential. Issues like tool wear, material variation, or operator error can arise during bulk production that were not present during sampling.

A 'golden sample' is the pre-production sample approved by the client, used as the quality standard for mass production.True

This physical sample serves as the ultimate, non-negotiable reference for quality control inspectors to compare against the units being produced. It is more reliable than photos or drawings.

How Can You Truly Guarantee Quality for Your Bamboo Products?

You can't be at the factory 24/7. So how do you ensure every product meets your standards? Relying on the factory's internal QC alone is a huge and costly risk.

Guarantee quality with a multi-layered approach. Create a detailed quality control checklist[^4], use a third-party inspection service for key milestones, and have a clear agreement on how to handle defects. Never release final payment until quality is confirmed.

Dive Deeper: Building a Quality Assurance System

In my early days running my trading company, I learned a tough lesson by trusting a factory's "100% QC passed" report. The shipment arrived, and 30% of the products were defective. It was a disaster. Now, I build a system of checks and balances for every project. You need to control the quality process yourself. This means creating your own standards and having your own people check them. A third-party inspector acts as your eyes and ears in the factory. They are unbiased and work for you, not the factory. This is one of the best investments you can make to protect your business and ensure you get what you paid for.

Your Quality Guarantee Toolkit

| Tool | Description | How to Use It |

|---|---|---|

| QC Checklist | A detailed document listing all inspection points, tolerances, and pass/fail criteria. | Provide this to the factory and your third-party inspector. It leaves no room for interpretation. |

| Third-Party Inspection | Hire an independent company to inspect the goods at the factory. | Schedule a Pre-Shipment Inspection (PSI) when 80% of the order is complete but before it's packed. |

| Defect Classification | Define what constitutes a minor, major, or critical defect in your contract. | Example: A small scratch (minor), a crack (major), a safety hazard (critical). |

| Payment Terms | Structure your payment to hold leverage. | A common structure is 30% upfront and 70% after you receive and approve a passed inspection report. |

The factory's internal quality control is always sufficient to guarantee quality.False

While factories have their own QC, their standards may not align with yours, and they have a vested interest in shipping the product. An independent third-party inspection provides an unbiased assessment.

AQL (Acceptable Quality Limit) is a statistical standard used to determine inspection sample size and pass/fail criteria.True

Using AQL standards (e.g., AQL 2.5) is the professional industry method for conducting product inspections and making an objective decision on whether to accept or reject a shipment.

Why is the Sampling Stage So Critical?

You're eager to start production and sampling feels like a slow, expensive step. Is it really necessary to spend time and money on samples before placing the main order?

Sampling is your most important risk-reduction tool. It validates your design, tests the manufacturer's capability, and confirms material and finish choices before you commit to a large, expensive order. A good sample is proof the factory can deliver on its promises.

Dive Deeper: The Power of a Physical Sample

I never, ever skip the sampling stage. It's the moment your digital design becomes a physical object you can hold and test. It's where you catch issues that are invisible on a computer screen, like the feel of the finish, the actual color of the bamboo, or the weight of the product. I've had clients realize their design was slightly too big or too small only after holding the first sample. Fixing that on a sample costs a few hundred dollars; fixing it after making 10,000 units can bankrupt a project. At Moldle, our experienced technicians and sales engineers always emphasize that a perfect pre-production sample is the foundation of a successful project. It is your single source of truth.

Types of Samples and Their Purpose

| Sample Type | Purpose | What to Check |

|---|---|---|

| Prototype Sample | To test form, fit, and function. Often made with different methods (e.g., 3D printing, hand-carving). | Does the design work as intended? Are there any ergonomic issues? Is it easy to assemble? |

| Pre-Production Sample (PPS) | Made with the final production tooling and materials. This becomes your "golden sample". | Check everything: dimensions, material, color, finish, assembly, and packaging. It must be perfect. |

| Production Sample | A random sample taken from the actual bulk production run. | Use this to verify that the quality is consistent with the approved PPS during manufacturing. |

You can save money by skipping samples and going directly to mass production.False

This is extremely risky and a classic beginner's mistake. The cost of a sample is tiny compared to the potential loss of an entire production run of defective goods.

The Pre-Production Sample (PPS) must be made using the exact same materials and processes as the final bulk order.True

The purpose of the PPS is to be a perfect representation of what you will receive in your bulk order. Any deviation, no matter how small, invalidates its purpose as a quality benchmark.

Conclusion

Mastering bamboo wholesale involves finding the right partner, communicating with clear designs, and enforcing rigorous quality control. Follow these steps to turn your design into a successful, high-quality product.