How Can You Turn a Wooden Toy Idea into a Real Product?

Struggling to turn your brilliant wooden toy concept into a physical product? The path from a simple sketch to a market-ready item can seem complex and full of unknowns.

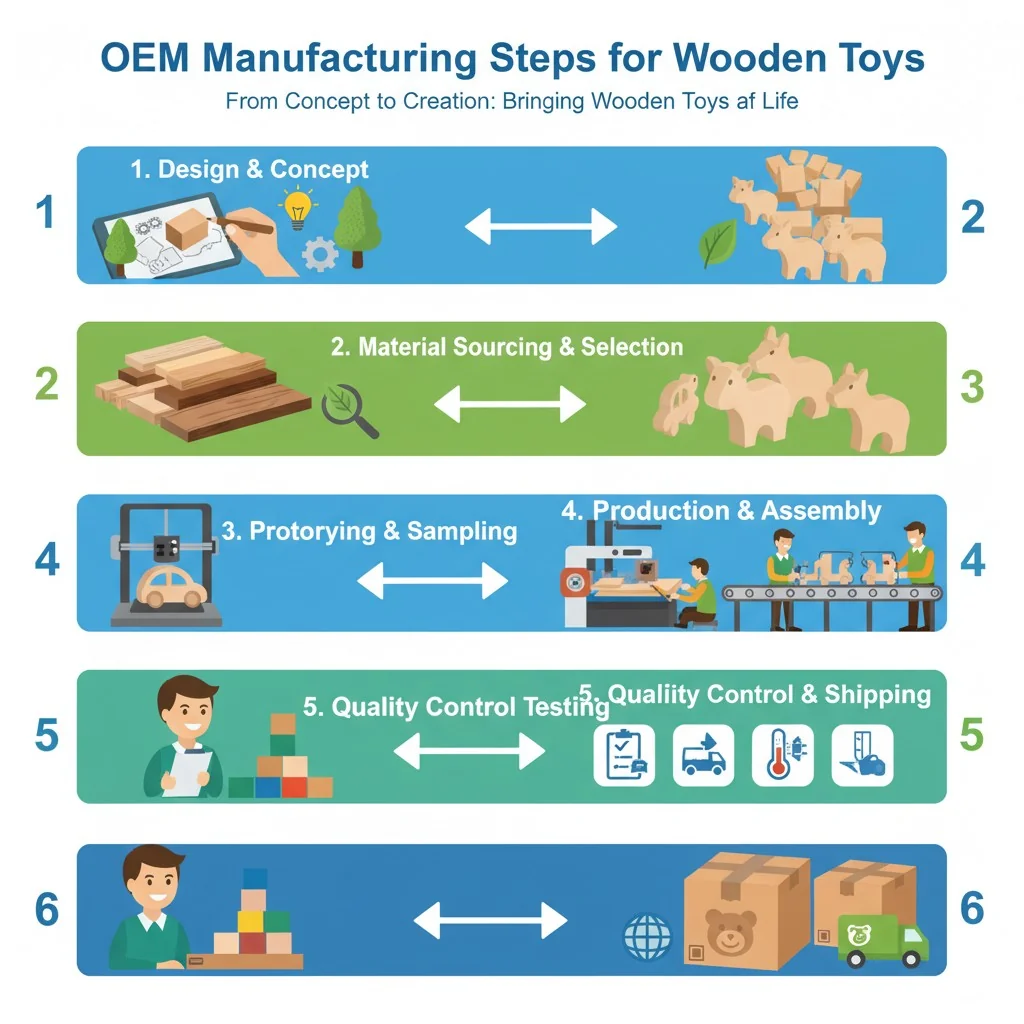

Turning a wooden toy idea into a real product involves a structured OEM manufacturing process[^1]. This includes initial design discussions, engineering and finalization, prototyping for approval, mass manufacturing, rigorous quality control, and finally, shipping. This systematic approach ensures your vision is realized accurately and efficiently.

It might sound like a lot, but when you break it down, it's a journey I've helped many clients navigate. I've seen firsthand how a simple idea on a napkin can become a successful product. The key is having a clear, transparent process and the right partner to guide you. Let's walk through each step, so you can see exactly how a simple concept becomes a high-quality wooden toy ready for the market.

The global wooden toys market was valued at over USD 24 billion in 2023 and is expected to grow.True

Market research reports from firms like Grand View Research and others confirm a growing market for wooden toys, driven by demand for sustainable and durable products.

All wooden toy manufacturers in China offer in-house design services from a simple sketch.False

This is an overgeneralization. While many full-service OEM manufacturers do, some factories are purely production-focused and require clients to provide complete, production-ready CAD files.

How Does a Chinese OEM Partner Bring Your Custom Wooden Toy to Life?

Finding a reliable overseas manufacturing partner can feel like a big risk. You worry about communication, quality, and whether your design will be understood. But a good partner removes that fear.

A dedicated OEM partner brings your toy to life through a collaborative six-step process: Listening & Discussing, Engineering & Design, Prototyping, Manufacturing, quality control[^2], and Shipping. This transparent workflow ensures your vision is accurately produced from concept to completion, keeping you in control at every stage.

I've found that the best manufacturing relationships are built on clear communication and a shared goal. It’s not just about placing an order; it’s about building a partnership. When I work with clients on a new toy, we look for a manufacturer who embraces this collaborative spirit. Let's break down what that process looks like in practice. It’s a system designed to catch problems early and ensure the final product is exactly what you imagined.

Step 1: Listening & Discussing

This is the foundation. A good partner doesn't just take your order; they listen. I remember a client who wanted to make a wooden animal puzzle. In our first call with the factory, we spent an hour just talking. We discussed the target age group, which helped us decide between durable beech wood and lighter pine. We talked about the feel, the structure of the interlocking pieces, and even preliminary ideas for the packaging. Every detail matters for safety and play value.

Step 2: Engineering Decisions & Final Design

After the initial discussion, the factory's engineers get to work. They take your concept, whether it's a detailed CAD file or a freehand sketch, and turn it into a professional design file optimized for manufacturing. They consider the wood grain, the best way to join parts, and how to make it durable. These final design files are then sent back to you for approval. This is a critical checkpoint. It’s your last chance to make changes before any physical work begins.

Step 3: Prototyping

Once you approve the design, they create a physical prototype. This is the exciting part where your idea becomes something you can hold. When the prototype arrives, you check everything: the size, the weight, the colors, the smoothness, and the function. I always tell my clients to be picky here. If something isn't right, you provide feedback, and the factory makes a new prototype. We once went through three rounds for a toy car just to get the wheel spin perfect. It's worth the time to get it right.

Step 4-6: Manufacturing, QC, and Shipping

With an approved prototype, mass production begins. A good partner will keep you updated with photos and progress reports. Throughout production, they perform their own quality checks. After everything is made, a final inspection happens. You can even hire a third-party inspector for extra peace of mind. Once everything passes, the toys are packed and shipped according to your instructions, whether it's to a warehouse or directly to your customers.

| Stage | Key Action | Your Role |

|---|---|---|

| 1. Discussion | Share ideas, materials, safety needs. | Provide clear concept and vision. |

| 2. Design | Engineers create production-ready files. | Review and approve final designs. |

| 3. prototyping[^3] | A physical sample is created. | Test, comment, and approve the sample. |

| 4. Manufacturing | Mass production begins. | Stay updated on progress. |

| 5. Quality Control | Internal and external inspections. | Option to hire 3rd party inspector. |

| 6. Shipping | Products are packed and delivered. | Provide final delivery instructions. |

Prototyping is a critical step for identifying design flaws before mass production.True

This is a fundamental principle of engineering and product development. A physical prototype allows for testing of fit, function, and ergonomics that cannot be fully simulated in CAD.

Third-party quality inspections are an unnecessary expense when working with experienced factories.False

While experienced factories have internal QC, a third-party inspection provides an unbiased, independent verification of quality, which is crucial for protecting your brand and investment.

What Key Factors Ensure Quality and Safety in Wooden Toy Manufacturing?

You've approved a perfect prototype, but how do you ensure every one of the 10,000 units is just as good and safe? A single quality issue can ruin your brand.

Key factors for quality and safety include material selection[^4] (non-toxic paints, sustainable wood), structural integrity checks, and multi-stage inspections. Adherence to international safety standards like ASTM F963 and EN-71 is non-negotiable and must be verified by internal and third-party testing.

From my years in manufacturing, I can tell you that quality isn't something you just check for at the end. It has to be built into every single step of the process, from the raw wood to the final box. For a product designer like Jacky, understanding these checkpoints is crucial for managing a project successfully and protecting the end-user. Let's dive deeper into the three pillars of quality assurance in wooden toy making.

Material Integrity and Safety

It all starts with the raw materials. You can't make a high-quality toy from bad wood.

- Wood Selection: We specify the type of wood, like beech for durability or pine for a lighter feel. The factory's first QC step is to verify the incoming lumber meets these specs and has the correct moisture content to prevent warping or cracking later.

- Paints and Finishes: This is a major safety point. All paints, stains, and lacquers must be certified non-toxic and child-safe. We require documentation from the paint supplier and often run our own tests to be certain. There is zero room for error here.

Multi-Stage Inspection Process

A single final inspection is not enough. Quality must be monitored throughout the production line. I insist on a process that looks something like this:

- In-Process Inspection: As parts are cut, sanded, and painted, workers and line managers perform checks. Are the dimensions correct? Is the surface free of splinters? Is the paint coverage even? Catching a mistake on one part is much cheaper than finding it in 1,000 assembled toys.

- Final Internal Inspection: Before packing, a dedicated internal QC team checks a statistically significant sample (or 100% of the units, depending on the product) against a checklist based on the approved prototype.

- third-party inspection[^5]: I always recommend this for my clients. An independent inspector provides an unbiased report on the final product quality before you make the final payment. It's your ultimate safety net.

Adherence to International Standards

| Selling toys comes with legal responsibilities. Your product must meet the safety standards of the country you're selling in. | Standard | Region | Key Focus Areas |

|---|---|---|---|

| ASTM F963 | USA | Small parts (choking hazard), sharp points, lead and heavy metals. | |

| EN-71 | Europe | Flammability, chemical properties, mechanical and physical properties. | |

| ISO 8124 | International | A baseline standard often adapted by various countries. |

A reliable manufacturer will not only be familiar with these standards but will also be able to provide documentation and test reports from accredited labs to prove compliance. This isn't just paperwork; it's proof that your toy is safe for a child to play with.

The EN-71 standard specifies safety requirements for toys sold in the European Union.True

This is a fact. EN-71 is the harmonized European Standard for toy safety and is a legal requirement for any toy sold within the EU.

A smooth finish on a wooden toy is purely for aesthetics.False

This is false. A smooth, splinter-free finish is a critical safety requirement to prevent cuts and injuries to a child's delicate skin.

Conclusion

The journey from a wooden toy concept to a finished product is a clear, manageable process with the right OEM partner. Focus on collaboration, prototyping, and rigorous quality control to succeed.

References

[^1]: Understanding the OEM manufacturing process is crucial for anyone looking to bring a toy idea to market.

[^2]: Quality control is essential in toy manufacturing to ensure safety and compliance with standards.

[^3]: Prototyping helps identify design flaws early, ensuring the final product meets expectations.

[^4]: Choosing the right materials is vital for safety and durability in toy manufacturing.

[^5]: Third-party inspections provide unbiased quality verification, crucial for brand protection.