How To Make Wooden Toy Cost Less?

High manufacturing costs are eating into your wooden toy profits. You've optimized designs, but material and labor keep rising, making it hard to compete. The secret is a smarter manufacturing strategy.

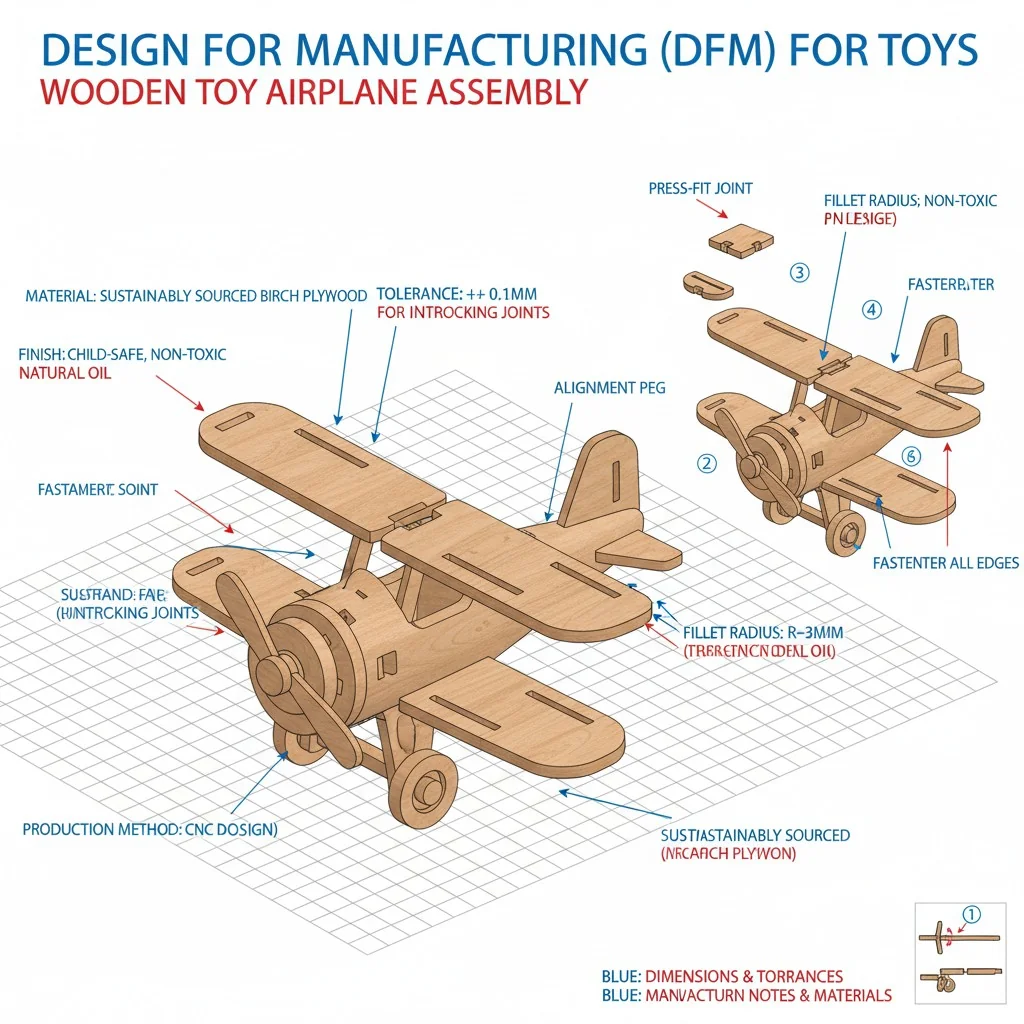

To lower wooden toy costs, focus on Design for Manufacturing (DFM). Simplify shapes, reduce the number of parts, and choose cost-effective wood types[^1]. Also, consider partnering with an experienced overseas manufacturer who has optimized supply chains and production processes.

You might think your design is already as simple as it can be. I've been in this industry for over 20 years, and I've seen small tweaks save companies thousands of dollars. The principles that make plastic molding efficient can also revolutionize how you make wooden toys. It's all about looking at your product from a manufacturer's point of view. Let's look at where the real savings are hidden.

All hardwoods are more expensive than all softwoods for toy manufacturing.False

This is a common oversimplification. While many hardwoods are premium, common and sustainable hardwoods like Beech or Rubberwood can be more cost-effective in bulk than some rarer or specialized softwoods. Pricing depends on availability, region, and purchase volume.

Using non-toxic, water-based paints is a key requirement for children's toys sold in most Western markets.True

Correct. Regulations like Europe's EN-71 and the USA's ASTM F963 mandate strict limits on lead and other toxic elements in toy paints and coatings to ensure child safety. Water-based, non-toxic finishes are the industry standard for compliance.

Can Partnering with an Experienced Chinese Manufacturer Really Cut Costs?

You're hesitant about overseas manufacturing, worried about quality, communication, and risks. Horror stories of bad samples and missed deadlines make you stick with expensive local options. But the right partner is a game-changer.

Yes, partnering with an experienced Chinese manufacturer can significantly cut costs. They offer lower labor rates, established supply chains for materials, and economies of scale. The key is finding a vetted, reliable partner with a proven track record and clear communication processes.

When I started my trading company, I spent months on the ground in China visiting factories. I learned to spot the good ones from the bad ones. The best manufacturers, especially those with 20+ years of experience working with world-famous brands, aren't just cheaper. They bring a level of expertise that can actually improve your product. They have seen thousands of designs and know what works. They can suggest material changes or design tweaks that save money without sacrificing quality. The risk is real if you choose blindly, but the reward for finding a great partner is huge. It’s about more than just cost; it’s about leveraging their scale and experience.

Comparing Production Options

Let's break down the real differences you'll face. It's not just about the price tag.

| Feature | Local Manufacturer | Experienced Overseas Partner |

|---|---|---|

| Unit Cost | High | Low |

| Expertise | Varies | High (often specialized) |

| Communication | Easy (same language/timezone) | Can be challenging |

| Quality Control | Easier to oversee in person | Requires a strict process |

| Shipping | Fast and cheap | Slower and more costly |

As you can see, the big win overseas is the unit cost. Your job, as a designer or business owner, is to manage the other factors. With a good partner, communication becomes smooth, and a solid quality control plan makes the distance irrelevant.

Shipping costs from China always negate the savings from lower production costs.False

While shipping is a significant expense, it's calculated into the 'landed cost'. For medium to large production runs, the per-unit savings on manufacturing are typically so substantial that they far outweigh the costs of freight and import duties.

A Bill of Materials (BOM) is essential for getting an accurate quote from any manufacturer, domestic or overseas.True

Absolutely. A detailed BOM lists every single part, material, screw, and drop of paint. Without it, manufacturers have to guess, which leads to inaccurate quotes and potential cost overruns later. It is a foundational document for professional manufacturing.

How Can Design for Manufacturing (DFM) Make Your Wooden Toys Cheaper?

Your beautiful toy designs are getting rejected by the production team for being too complex or expensive to make. Every design revision costs you time and money, pushing your launch date further away.

Design for Manufacturing (DFM) reduces costs by simplifying your toy's design for easier production. This means using fewer parts, standardizing components, choosing cost-effective materials, and designing shapes that are easy to cut, sand, and assemble.

In the mold world, we live and breathe DFM. A tiny change in a draft angle or wall thickness can save thousands of dollars over a production run. The exact same logic applies to wood. I once helped a client redesign a wooden toy car. The original design had wheels that were a complex two-part assembly. We worked with the factory to change it to a single, slightly thicker wheel shape that could be cut and finished in one process. This simple change cut their total production cost by 15% and made assembly much faster. You have to think about every single step: How is this cut? How is it sanded? How many pieces need to be glued? Each step adds cost.

Key DFM Strategies for Wooden Toys

Applying DFM doesn't mean making your toy boring. It means making it smart.

| DFM Tactic | Cost Impact | Example |

|---|---|---|

| Part Consolidation | High | Designing a toy body as one CNC-carved piece instead of three separate pieces that need to be glued together. |

| Material Selection | High | Using Beech wood, which is hard and durable, instead of a more expensive wood like Oak for a mass-market toy. |

| Process Optimization | Medium | Designing parts with simple curves that can be batch-sanded in a tumbler instead of complex shapes requiring hand-sanding. |

| Standardize Parts | Medium | Using the same size wheel and axle across five different toy vehicles in your product line. |

The type of wood finish, such as paint versus oil, has a negligible impact on the final cost of a toy.False

This is incorrect. The cost of the finishing material itself, the labor or machinery required for application, and the time needed for drying or curing can vary significantly. A multi-layer spray paint finish is often more expensive than a simple dip-and-dry oil finish.

Reducing the number of unique parts in a toy assembly can lower costs by simplifying inventory management and assembly labor.True

This is a core principle of DFM. Fewer unique parts (SKUs) mean simpler logistics, less risk of stock-outs for one component, and faster, more repetitive assembly tasks, all of which reduce overall costs.

What Should a New Importer Know Before Sourcing Toys from China?

You've found a potential manufacturer in China, but the import process seems like a confusing maze of paperwork and regulations. You're worried about making a costly mistake with customs, safety certifications[^2], or payments.

A new importer must understand safety certifications (like ASTM F963), quality control procedures[^3] (factory audits, pre-shipment inspections), payment terms (like 30% deposit, 70% on completion), and shipping logistics (Incoterms like FOB or EXW).

I've guided many clients through this process, and I can help you too. I remember my first big import deal years ago. I was so focused on the product price that I almost forgot to budget for import duties[^4] and mandatory lab testing. It was a close call that taught me a valuable lesson. That's why I always tell new importers to calculate their full "landed cost," which includes the factory price plus shipping, insurance, duties, and testing. Don't get surprised by hidden costs. A good manufacturing partner will be transparent about what they cover, but the ultimate responsibility for importing legally and safely is yours. It seems intimidating, but it's just a process you can learn.

Your First Import Checklist

Here are the absolute basics you need to manage.

| Import Step | Key Consideration | My Advice |

|---|---|---|

| Safety & Compliance | Does the toy meet safety standards for your target market (e.g., ASTM F963 in the US)? | Always request compliance certificates from the factory and budget for independent third-party lab testing. Do not skip this. |

| Quality Control (QC) | How will you ensure the final product matches the approved sample? | Hire a third-party inspection service to check the goods at the factory before you pay the final balance. It's a small cost for huge peace of mind. |

| Payments & Logistics | What are the payment terms? Who handles shipping? | Never pay 100% upfront. A common term is 30% deposit and 70% after the goods pass inspection. Understand Incoterms; FOB (Free On Board) is common and means you handle shipping from the Chinese port. |

FOB (Free On Board) means the seller is responsible for all shipping costs to your warehouse.False

This is a critical misunderstanding. FOB means the seller's responsibility ends once the goods are loaded onto the shipping vessel at the port of origin. The buyer is responsible for the main sea freight, insurance, customs clearance, and domestic transport.

Third-party inspection services can be hired to perform quality checks at the factory in China before you make the final payment.True

Correct. Companies like SGS, Intertek, and QIMA specialize in this. They act as your eyes and ears on the ground, verifying quality, quantity, and packing requirements against your specifications, which is a crucial step to mitigate risk.

Conclusion

Reducing wooden toy costs is achievable. Focus on smart design, find the right manufacturing partner, and manage your import process carefully. You can make great products affordably.

Reference

[^1]: Exploring cost-effective wood types can lead to significant savings in production.

[^2]: Knowing safety certifications is crucial for compliance and avoiding costly mistakes.

[^3]: Implementing effective quality control can ensure product quality and reduce risks.

[^4]: Understanding import duties is essential for calculating the true landed cost of products.