How Do You Find Reliable Wooden Toy Manufacturers in China?

Sourcing wooden toys from China feels risky. You worry about safety, quality, and finding a partner you can trust. A bad choice can lead to recalls, lost money, and a damaged brand.

Finding a reliable Chinese wooden toy manufacturer means doing your homework. You must verify safety certifications like EN71[^1] and ASTM, check for valid FSC certification, and focus on production hubs like Zhejiang. It's also key to understand their OEM/ODM services and specify your quality control needs.

Finding the right manufacturing partner is about more than just a good price. In my years of running a trading company, I've seen countless projects succeed or fail based on the initial supplier choice. A great partner becomes an extension of your team, but a poor one creates endless problems. Let's break down exactly what you need to look for, step by step, to ensure you find a great one.

All wooden toy manufacturers in China have export licenses.False

While many do, not all factories, especially smaller ones, have direct export licenses. They often work through trading companies. It's a crucial point to verify early on.

China is the world's largest toy exporter.True

China dominates the global toy market, accounting for a significant majority of all toys produced and exported worldwide, including wooden toys.

Which Chinese Wooden Toy Manufacturers Meet EN71 and ASTM Safety Standards?

Worried your toys won't pass safety checks in Europe or the US? It's a common fear. A failed test means lost money, a damaged brand, and potential legal trouble.

Many top-tier, export-focused Chinese wooden toy manufacturers comply with EN71 (Europe) and ASTM F963[^2] (USA). You must request and verify their testing certificates from accredited labs like SGS, TUV, or Intertek. Never just take their word for it; always ask for the full reports.

When I work with clients, this is the first non-negotiable step. A factory that can't produce valid, recent safety reports for similar products is an immediate red flag. These standards are not just suggestions; they are legal requirements for market access. A professional factory knows this and will have the documentation ready. They understand that safety is the foundation of the toy business. Let's look at what these standards actually cover.

Understanding the Key Standards

- EN71 (European Standard): This is the mandatory safety standard for toys sold in the European Union. It's a comprehensive set of rules covering everything from physical properties to chemical content.

- ASTM F963 (US Standard): This is the legal standard for toy safety in the United States. It is also very thorough, with a strong focus on preventing common toy-related injuries.

EN71 vs. ASTM F963: A Quick Comparison

| Feature | EN71 (EU) | ASTM F963 (USA) |

|---|---|---|

| Primary Focus | Overall safety, with strong emphasis on chemical migration (e.g., heavy metals in paints). | Physical and mechanical safety to prevent injuries (choking, sharp points, etc.). |

| Chemical Testing | Tests for the migration of 19 different heavy metals. | Tests for the total content of 8 heavy metals, with a focus on lead. |

| Flammability | Has specific tests for flammability of different toy types. | Includes flammability requirements, particularly for toys a child might wear. |

| Small Parts | Uses a "small parts cylinder" to test for choking hazards for children under 36 months. | Also uses a "small parts cylinder" with very similar dimensions and purpose. |

If a toy passes EN71, it automatically passes ASTM F963.False

While there is significant overlap, the chemical testing requirements and some physical test methods differ. A product must be tested specifically for each standard to ensure compliance in both the EU and US markets.

ASTM F963 is a legal requirement for all toys sold in the USA.True

The Consumer Product Safety Improvement Act (CPSIA) of 2008 made ASTM F963 a mandatory consumer product safety standard in the United States.

How Do FSC Certification Rates Vary Among Top China Wooden Toy Makers?

Your customers demand sustainable products. But how do you prove your wood is responsibly sourced? Without proof, you lose trust and sales, especially with environmentally conscious buyers.

FSC (Forest Stewardship Council) certification is not standard across all Chinese toy makers. High-end, export-oriented manufacturers are far more likely to have it. You must verify their FSC Chain of Custody (CoC) certificate number on the official FSC database to ensure it's current and valid.

I've seen factories claim to use "eco-friendly wood," but that's just a marketing term. FSC is different. It's a rigorous, third-party verification system that traces the wood from the forest to the final product. For brands targeting markets in Europe or North America, this is becoming less of a "nice-to-have" and more of a "must-have." It shows a commitment to quality and ethics that goes beyond the product itself. Verifying a supplier's claim is easy and essential.

Understanding FSC

- What is it? The Forest Stewardship Council (FSC) is a global organization that certifies forests to ensure they are managed responsibly. This covers environmental, social, and economic aspects.

- Chain of Custody (CoC): For a toy to be sold with the FSC label, every company in the supply chain—from the forest to the factory to the distributor—must have FSC CoC certification. This ensures the certified wood is tracked and not mixed with uncertified sources.

- How to Verify: Go to the official FSC public search database (

info.fsc.org). You can search by the company's name or their FSC license code (e.g., FSC-CXXXXXX). This will tell you if their certificate is valid, what products it covers, and when it expires.

All wood from China is FSC certified.False

This is incorrect. A very small percentage of China's forests are FSC certified. Most FSC-certified wood used by Chinese manufacturers is imported from other countries.

FSC certification can increase a product's retail price.True

The cost of certified wood and maintaining the Chain of Custody certification often leads to a higher production cost, which is typically passed on to the consumer. However, many consumers are willing to pay a premium for sustainably sourced products.

Why Are Zhejiang and Shantou Hubs for Wooden Toy Production in China?

Searching all of China for a supplier is overwhelming. Where do you even start? Wasting time and money visiting factories in the wrong regions is a common mistake for newcomers.

Zhejiang province[^3], especially Yunhe county, is the heart of China's wooden toy industry. Shantou, in Guangdong province, is a massive general toy hub. Focusing on these areas makes sourcing efficient due to their concentrated supply chains, skilled labor, and deep industry experience.

When I first started, I learned quickly that industries in China are highly clustered. If you want to make socks, you go to one city; if you want electronics, you go to another. For wooden toys, the primary destination is Yunhe in Zhejiang. It's called "China's Wooden Toy City" for a reason. Nearly the entire town revolves around this industry. Shantou is a different beast—it's a toy superpower, but its strength is more in plastics and electronics. Knowing the difference saves you a lot of time.

The Two Main Hubs

- Zhejiang (Specifically Yunhe): This is the specialist. The entire ecosystem is built around wooden toys. You'll find raw material suppliers (for woods like beech, pine, and rubberwood), processing workshops, paint shops, and assembly factories all within a small area. This deep specialization means they have incredible expertise and efficiency for all-wood or primarily wood products.

- Shantou (Specifically Chenghai): This is the generalist. Chenghai is one of the largest toy production bases in the world, but it's famous for plastic, electronic, and RC toys. While you can find wooden toy makers here, the main advantage is for hybrid toys—for example, a wooden train set that includes plastic tracks or electronic sound components. The access to a diverse range of component suppliers is a huge plus.

Zhejiang vs. Shantou

| Factor | Zhejiang (Yunhe) | Shantou (Chenghai) |

|---|---|---|

| Specialization | Wooden Toys | Plastic & Electronic Toys |

| Supply Chain | Focused on wood, paints, finishes. | Diverse; plastics, motors, PCBs, etc. |

| Best For | Classic, high-quality wooden toys. | Hybrid toys mixing wood with other materials. |

| Experience | Generations of woodworking expertise. | Expertise in high-volume, complex assembly. |

Yunhe county produces over 50% of all wooden toys made in China.True

Official reports and industry data consistently show that Yunhe is the dominant production base, accounting for more than half of China's total output and a significant portion of global wooden toy exports.

Shantou is the best place to source high-end, artisanal wooden toys.False

While Shantou is a massive toy hub, its primary strength is in mass-market plastic and electronic toys. For artisanal or high-end wooden toys, Zhejiang (Yunhe) is the more specialized and appropriate region.

How Can I Evaluate OEM Versus ODM Services From Chinese Suppliers?

You have a great design, but can the factory actually make it? Or maybe you just have an idea and need a product to sell? Choosing the wrong service model—OEM or ODM—can stall your project before it even starts.

Evaluate OEM (Original Equipment Manufacturer) by their technical ability to produce your exact design. Check their engineering team and past projects. Evaluate ODM (Original Design Manufacturer) by their existing product catalog, R&D team, and ability to customize. Your choice depends on whether you have a finished design.

This is a fundamental choice. As a designer like Jacky, you'll likely lean towards OEM because you have the skills to create a complete product design. But sometimes, an ODM supplier with a great existing product that only needs a few tweaks can get you to market much faster. I always advise clients to be clear about what they need. Don't approach an OEM factory with a vague idea, and don't expect groundbreaking innovation from a factory that only does ODM.

Making the Right Choice

- Choose OEM if: You have a complete, detailed product design and technical package. You want full control over the final product and own the intellectual property. Your goal is to find a factory that can execute your vision perfectly. When evaluating an OEM, I look at their machinery, their engineers' experience, and their quality control on similar products.

- Choose ODM if: You have a product idea but not a full design, or you want to private-label an existing product. Your goal is speed to market and lower R&D costs. When evaluating an ODM, I look at the quality and appeal of their current catalog. I also ask how much customization they allow—can you change colors, materials, and packaging?

OEM vs. ODM at a Glance

| Aspect | OEM (Original Equipment Manufacturer) | ODM (Original Design Manufacturer) |

|---|---|---|

| Your Role | Provide a complete, detailed design. | Provide an idea or choose from a catalog. |

| Supplier's Role | Manufactures your design. | Designs and manufactures the product. |

| Pros | Full control, unique product, IP ownership. | Fast to market, lower R&D cost. |

| Cons | High R&D cost, longer development time. | Not a unique product, limited control. |

| Best For | Brands with strong design capabilities. | Brands wanting to enter a market quickly. |

ODM means you can't change anything about the product.False

This is a common misconception. Most ODM suppliers offer 'private label' services, which allow for customization of branding, logos, colors, and packaging on their existing product designs.

With OEM, the buyer owns the intellectual property (IP) for the design.True

In a typical OEM relationship, the buyer provides the design and therefore owns the IP. The manufacturer is contracted solely to produce it. This should always be clarified in your manufacturing agreement.

What Are the Essential Quality Tests for Wooden Toys?

A toy looks good, but is it safe? A single failure in a physical test can lead to a product recall and destroy your brand's reputation. You must know what to test for to protect children and your business.

Essential physical tests include torque, tension, drop, and compression tests to ensure durability. Safety-critical tests include the small part, sharp point, and sharp edge tests. These procedures are defined by global standards like EN71 and ASTM F963 and must be part of your quality plan.

In my experience, this is where some brands try to cut corners, and it's a huge mistake. I always insist on a detailed Quality Control Inspection Checklist[^4] that includes these specific physical tests. A good factory will have the equipment and procedures to do this in-house. You can't just test one "golden sample." You need to perform these checks on a percentage of every production run to ensure consistent quality and safety.

Key Physical & Mechanical Tests

| Test Name | Purpose |

|---|---|

| Soaking Test | Simulates a child putting the toy in their mouth. Checks if paint flakes or small parts detach after being submerged in water. |

| Torque & Tension Test | Twists and pulls on components (like wheels, arms, knobs) with a specific force to ensure they don't break off and create a choking hazard. |

| Compression Test | Applies a heavy force to the toy to ensure it doesn't crack or break, exposing sharp edges or small parts. |

| Sharp Point Test | Uses a special tool to check if any point on the toy is sharp enough to puncture a child's skin. |

| Small Part Test | Determines if the toy itself, or any piece that breaks off, is small enough to fit entirely within a "small parts cylinder," posing a choking hazard. |

| Oven Conditioning Test | Simulates extreme temperature changes during shipping to see if the wood cracks or glue joints fail. |

| Salt Spray Test | Checks for corrosion on any metal parts, like screws or axles, by exposing them to a saline mist. |

| ISO 8124 Stability Test | For large, ride-on toys, this test ensures they won't easily tip over when a child is using them. |

These physical tests are optional if the toy has passed chemical tests.False

Chemical safety (like lead in paint) and physical/mechanical safety are two separate, equally important requirements. A toy must pass both types of tests to be considered safe and compliant.

A drop test is a standard procedure for toy testing.True

Drop tests, where a toy is dropped multiple times onto a hard surface from a specified height, are a standard part of both EN71 and ASTM F963 to simulate foreseeable use and abuse.

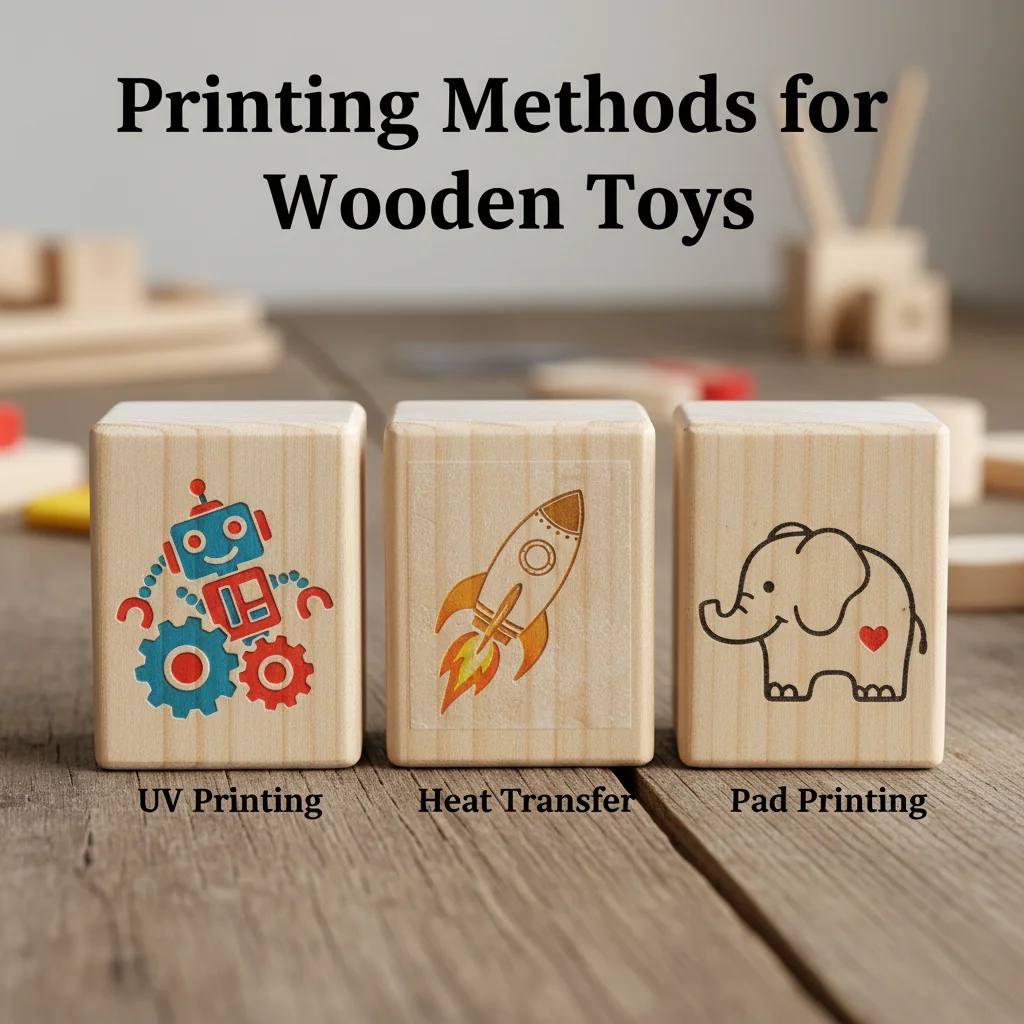

What Are the Best Printing Methods for Wooden Toys?

The graphics on your toy are peeling or look cheap. This ruins the product's value and can even be a safety hazard. Choosing the wrong printing method can make a great toy look bad.

The best method depends on your design, volume, and budget. Heat transfer is great for complex, multi-color images. Pad printing is perfect for curved surfaces. UV printing offers durable, high-resolution results directly on the wood, and silk screening is a classic, durable choice for simpler graphics.

The finish and graphics are what bring a wooden toy to life. I've seen beautiful wood ruined by a cheap-looking print that peels off. When discussing printing with a factory, you need to be specific. It's not just about the image; it's about durability and safety. The inks used must also be non-toxic and compliant with EN71/ASTM standards. Let's compare the most common methods.

Comparing Printing Options

-

Heat Transfer Printing: An image is printed on a special film and then transferred to the wood using heat and pressure. It's excellent for photorealistic or highly detailed, multi-color graphics. The quality can vary, so you need to test for durability to ensure it doesn't peel.

-

UV Printing: A digital printer applies ink directly to the wood surface, and the ink is instantly cured (hardened) by ultraviolet light. This method is very durable, scratch-resistant, and allows for high-resolution, full-color printing. It's a modern and increasingly popular choice.

-

Pad Printing: A flexible silicone pad picks up ink from an etched plate and presses it onto the toy. This is the go-to method for printing on irregular or curved surfaces, like the face on a small wooden figure.

It's

typically used for smaller logos or graphics with one or two colors. -

Silk Screen Printing: Ink is pushed through a mesh screen onto the wood. It's a traditional method that produces a thick, durable layer of ink. It's best for simple, bold graphics with a limited number of colors, and it's very cost-effective at high volumes.

Which Printing Method to Choose?

| Method | Best For | Durability | Cost (High Volume) |

|---|---|---|---|

| Heat Transfer | Complex, photorealistic images. | Good to Very Good | Low |

| UV Printing | High-resolution, full-color graphics. | Excellent | Medium |

| Pad Printing | Curved or irregular surfaces, logos. | Very Good | Low |

| Silk Screen | Simple, bold graphics (1-3 colors). | Excellent | Very Low |

UV printing ink is toxic.False

While liquid UV ink requires careful handling, once it is cured by UV light, it becomes a solid, inert plastic that is non-toxic and very safe, which is why it's widely used for toys and food packaging.

Heat transfer is always the cheapest printing option.False

While the per-unit cost can be low at high volumes, the initial setup for creating the films can be expensive. For very small runs with simple graphics, silk screening or pad printing might be cheaper.

What Packaging Options Should I Consider for Wooden Toys?

Your beautiful toy arrives at the customer's home damaged, or it looks unappealing on a store shelf. Poor packaging can destroy your product and your sales before the customer even touches the toy.

Your packaging must balance protection, cost, and retail appeal. Color boxes with windows work well for retail, while sturdy mail-order boxes are essential for e-commerce. Always perform transit testing (like drop tests) to ensure your packaging can survive shipping.

I always tell my clients: your packaging is the first physical interaction a customer has with your brand. It's your silent salesman on the shelf and the protector of your investment during shipping. Don't treat it as an afterthought. A great box design can increase perceived value, while a strong structure prevents costly returns and damage. You also need to think about sustainability, as many consumers now prefer paper-based, plastic-free options.

Key Packaging Considerations

- Retail Packaging: This is all about shelf appeal. A "color box" made of printed cardstock is standard. A plastic or PLA window can showcase the product. Custom-designed paper pulp or cardboard inserts hold the toy securely and add a premium feel. Good graphic design is critical here.

- E-commerce Packaging: The priority here is protection. This often means a sturdy, corrugated "mailer box" (usually plain brown or white). The key is the interior. Use die-cut cardboard inserts, honeycomb paper, or tissue paper to cushion the product and prevent it from moving around. The goal is to pass a 1.5-meter drop test without any product damage.

- Sustainable Options: There's a strong trend away from plastic. Consider using recycled cardboard for your boxes, soy-based inks for printing, and avoiding plastic windows or inserts. Using paper-based void fill instead of bubble wrap is another easy switch that customers appreciate.

A good-looking box is all that matters for retail.False

While aesthetics are crucial for shelf appeal, the box must also be structurally sound to protect the product in transit from the factory to the warehouse and to the store. It also needs to display mandatory legal information.

E-commerce packaging must be able to survive a drop test.True

Standard practice, often required by large platforms like Amazon, is for product packaging to pass transit tests, including drop tests from various heights and angles, to simulate the harsh environment of the parcel delivery system.

Custom Wooden Toy tips For New Wooden Toy Buyer

Finding a reliable wooden toy maker in China is a process of careful verification. Focus on certifications, regional strengths, and clear communication of your quality, printing, and packaging needs to build a successful partnership.

Case Study: Custom Wooden Advent Calendar for a U.S. Customer

We recently worked with a U.S. customer who wanted to develop a custom wooden advent calendar. This was her very first time importing from China, so she was both excited and cautious. She wanted to reduce costs but also needed assurance that the manufacturer was trustworthy. With no professional designs—only a handmade cardboard mock-up—she turned to us for guidance.

Step 1: Choosing the Right Materials

After reviewing her mock-up and dimensions, we suggested using plywood for the back panel and pine for the blocks. Basswood was another option, but since it is more expensive, the pine-and-plywood combination offered the best cost-performance balance.

Because the calendar was large, material selection was crucial to control costs. We also recommended leaving the outer frame in natural wood (no paint) to save money, while applying a clear lacquer finish to the blocks for durability and appearance.

Spray vs. Roll Lacquer

The customer asked about finishing options, so we explained the difference:

Spray lacquer: Delivers a smoother, more even finish, but the cost is higher.

Roll lacquer: More cost-effective, while still offering good protection.

The price difference is about $1.43 per unit, which becomes significant in bulk orders. For this project, we recommended roll lacquer as the smarter option for cost control.

Step 2: Packaging Solutions

We offered laminated color boxes for retail presentation. Color boxes can come with glossy, matte, or special finishes for a premium look. As a simpler option, plain white boxes were also available. The customer chose color boxes, which we agreed would add more shelf appeal.

Step 3: Sampling & Drop Test

The customer happily paid the sample fee, and we proceeded with development. Our team prepared technical drawings within one week, received approval, and then produced samples.

During the sample stage, we also conducted a drop test to evaluate packaging strength and product durability. This test ensures that the advent calendar can withstand transportation and handling without damage. After confirming the results, we shipped the samples via international courier.

Step 4: Feedback on Samples

When the customer received the samples, she noticed two issues:

Some graphics were off-center – this is a known risk with manual heat transfer printing.

Image clarity was not ideal – because the designs she provided were hand-drawn sketches, not professional vector files.

We explained the difference and showed her comparison photos of block toys we produce for Melissa & Doug, which use vector artwork and achieve very crisp results.

It’s also worth noting:

During early sampling, we use UV printing (fast, flexible, suitable for mock-ups).

For final confirmation, we switch to heat transfer printing (closer to mass production).

Heat transfer printing has an additional cost, which we always clarify in advance.

Step 5: Safety Testing & Certification

Since this was a children’s product, U.S. regulations required compliance with:

ASTM F963 Standard

CPSIA

FHSA Regulation

Age Grade: 3+

We worked with Intertek Testing Services, one of the world’s leading labs. Testing takes about 15 days, with costs covered by the customer. We handled sample preparation and shipping directly to the lab.

Step 6: Shipping & Timing Challenges

For Christmas products like advent calendars, timing is critical. Sea freight to the U.S. normally takes 25–45 days, depending on the route. Fast ships are available, but the costs are much higher.

Our customer needed the calendars to arrive by October. Unfortunately, because of 2–3 rounds of sample revisions, there wasn’t enough time left for testing, shipping, and customs clearance. We decided to postpone production until the following year.

It’s important to remember that if product designs are modified the next season, retesting may be required, which adds time and cost.

Key Lessons for First-Time custom wooden Toy Importers

This project offers valuable insights for buyers new to importing wooden toys from China:

Material choice impacts both quality and cost.

Spray vs. roll lacquer has a cost difference of about $1.43 per unit.

Professional vector files are essential for sharp, centered printing.

Testing is mandatory and takes at least 15 days—factor this into your timeline.

Drop tests during sampling help verify durability and packaging safety.

Sea freight takes 25–45 days, so plan early for seasonal items.

Although this advent calendar missed the Christmas deadline, it successfully passed safety testing, and with all the development steps complete, mass production will run much more smoothly next year.

I wrote this case study is a good reminder that developing custom wooden toys requires careful planning, clear communication, and extra time—especially for seasonal products. Although this project put for next year.Developing this new wood product was a rewarding experience. The client gave me rave reviews for my professional expertise in wooden toys and my communication throughout the process. Their satisfaction has made my day!And I recommend another hot selling product for her.She is very happy and placed order already. The order will be shipped in OCtober,2025.I hope a big success.

References

[^1]: Understanding EN71 is crucial for ensuring toy safety compliance in Europe, protecting your brand and customers.

[^2]: ASTM F963 is essential for compliance in the US market, ensuring your toys meet legal safety requirements.

[^3]: Zhejiang is a key hub for wooden toys, offering specialized expertise and efficient supply chains for quality production.

[^4]: A thorough checklist is vital for ensuring toy safety and quality, protecting your brand from recalls and legal issues.