Struggling to design products that are durable, safe, and also feel special to the user? It’s a common challenge. Let's look at wooden toys to see how they master this balance.

The best wooden food toys[^1] are masterpieces of design for manufacturing. They use select materials like beechwood, feature safe, rounded edges, and are made with efficient processes like CNC machining. These elements create a product that is both beautiful and built to last for years.

I've spent my life in the manufacturing world, mostly with molds and plastics. But I've always admired the simple genius of a well-made wooden product. It seems basic, but the design and production thinking behind a high-quality wooden toy holds lessons for all of us, even those of us working on complex electronics components. It all comes down to understanding your material and your process. Let's dig into why wood is such a fantastic material and what we can learn from how these toys are made.

Wooden toys can improve a child's cognitive skills, including problem-solving and spatial awareness.True

Studies have shown that the open-ended nature of simple toys like wooden blocks and play food encourages imaginative scenarios and problem-solving, which are foundational for cognitive development.

All wooden toys are environmentally friendly.False

While wood is a renewable resource, the environmental impact depends on factors like sustainable forestry practices, the type of finish used (some paints and lacquers are not eco-friendly), and the carbon footprint of transportation.

Why are wooden toys the best for product design inspiration?

Choosing the right material for a project can be tough. Plastics are incredibly versatile, but they can sometimes result in products that feel disposable and raise environmental questions.

Wood is often the best choice for premium, long-lasting products because of its durability, natural feel, and sustainability. It offers a superior tactile experience that plastic can't replicate and develops character over time, making it a go-to material for creating items with lasting value.

When I started my journey in a mold factory, I learned everything about plastics. I know how they flow, how they shrink, and how to design a mold to get the perfect part. But I also learned that material choice[^2] is about more than just function; it's about feeling. A wooden toy feels solid and warm in your hand. A plastic one can feel hollow and cold. This "feel" is a key part of the user experience that every product designer, like Jacky, needs to consider. Let's break down the comparison from a manufacturing perspective.

Material Properties and Production

The choice between wood and plastic impacts the entire production line, from initial tooling to the final finish.

| Feature | Wood (e.g., Beech, Maple) | Plastic (e.g., ABS, PP) |

|---|---|---|

| Durability | High. Very resistant to breaking, though can dent. | Varies. Can become brittle over time or crack under impact. |

| Tooling | CNC programming, cutting tools, jigs. Lower initial cost for small batches. | Injection molds. High initial cost, but very low per-unit cost. |

| Safety | Naturally non-toxic (wood itself). Safety depends on the finish. | Can contain additives. Requires food-grade, non-toxic certification. |

| Aesthetics | Natural grain, warm feel. Each piece is unique. | Uniform color and texture. Can look and feel "cheap." |

| Weight | Heavier, providing a substantial feel. | Lightweight, which can be a pro or a con. |

As you can see, the decision isn't simple. For a premium product where tactile feel and durability are key, wood is a strong contender. For high-volume, low-cost items, plastic is often the only option. The lesson here is to match the material to the product's intended value and lifespan.

Beechwood is naturally antibacterial.True

Beechwood, along with other woods like maple and oak, contains natural antimicrobial properties that can inhibit the growth of bacteria on its surface, making it a hygienic choice for items like toys and cutting boards.

Wooden toys do not require any safety testing.False

All toys sold in major markets like the US and EU, regardless of material, must pass stringent safety tests for things like small parts (choking hazards), sharp edges, and toxic substances in paints or finishes.

What are hand-made wooden toys from a manufacturing view?

We often think mass production means sacrificing quality for speed. This can lead to generic products that don't really connect with people or build brand loyalty.

Looking at how "hand-made" or small-batch items are produced shows us a different way. It reveals techniques for creating high-value products that can, with the right strategy, be scaled up.

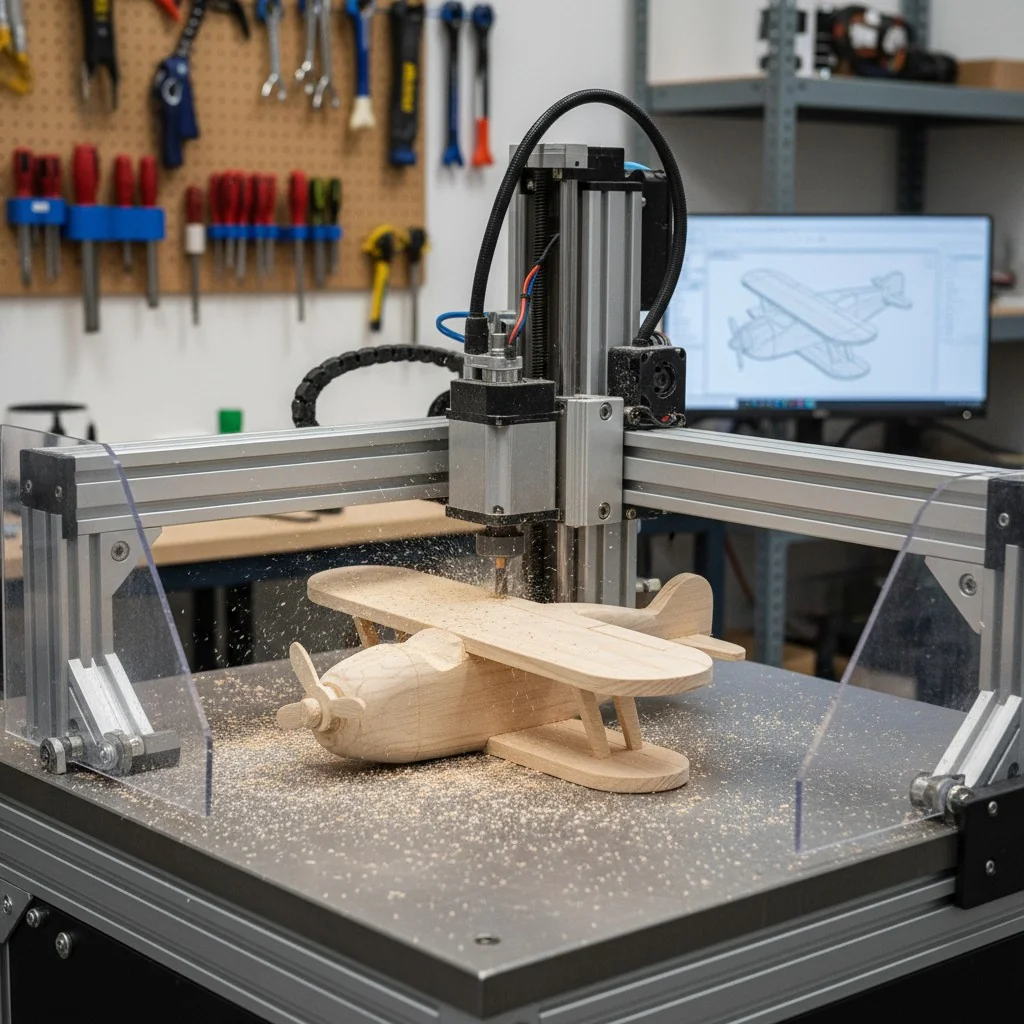

The term "hand-made" can be misleading. For a product like a wooden toy, it doesn't usually mean someone is carving it with a knife. It refers to a small-batch production process that involves a lot of skilled human touch alongside precise machinery. In my CNC trading business, I helped many clients set up these exact kinds of production lines. The process is a perfect blend of digital design[^3] and skilled craftsmanship, and it holds powerful lessons for any manufacturing field.

From Digital Design to Physical Product

Let's walk through how a modern "hand-made" wooden toy is born. It's a process that Jacky, our product designer, would be very familiar with.

- CAD and Design for Manufacturing (DFM): It all starts with a 3D model in a CAD program. The designer doesn't just create a shape. They have to think about the material. How will the wood grain look? Can this edge be rounded smoothly? Is this part strong enough? This is DFM for wood.

- CAM and CNC Programming: Next, the CAD file goes into a CAM (Computer-Aided Manufacturing) program. This software generates the toolpaths, or the exact instructions, for the CNC machine. This is the digital brain of the operation, just like when we prepare a file for creating a steel mold.

- Machining Process:

- CNC Lathe: For rounded parts like a wooden apple or a carrot, a CNC lathe is perfect. It spins the block of wood while a cutting tool shapes it with incredible precision.

- CNC Mill: For flatter or more complex shapes, like a slice of bread with crust details, a CNC mill is used. The cutting tool moves across the wood to carve out the design.

- Finishing: This is where the "hand" part really comes in. After machining, the parts are often tumbled in a large drum with abrasive media to smooth all the edges at once. Then, they are inspected and finished by hand, with non-toxic, food-safe oils or paints applied. This final human touch ensures quality.

This small-batch process allows for incredible detail and quality control. It's a great model for producing premium versions of any product, whether it's a toy or a high-end electronics enclosure.

CNC machines can only cut soft materials like wood and plastic.False

CNC (Computer Numerical Control) machines are used to cut a wide range of materials, including metals like aluminum, steel, and titanium. The machine's power, rigidity, and cutting tools are selected based on the material being worked.

Hand-finishing a product increases its perceived value.True

Products that are hand-finished often command a higher price and have a higher perceived value because the process implies greater attention to detail, quality control, and a level of craftsmanship not associated with fully automated mass production.

Conclusion

Wooden food toys are more than just playthings. They are excellent case studies in material science, design for manufacturing, and creating products with lasting quality and appeal for any industry.

References

[^1]: Explore how wooden food toys enhance creativity and cognitive skills in children.

[^2]: Explore the significance of selecting the right materials for product durability and user experience.

[^3]: Discover the impact of digital design on the efficiency and creativity of toy production.