WoddlonToy –Your Trusted China Wooden Toy Manufacturing Company & Wholesale Supplier

At WoddlonToy, we specialize in designing, manufacturing, and exporting high-quality wooden toys that inspire creativity, learning, and fun. With years of experience as a China wooden toy manufacturer, we help global brands, wholesalers, and retailers bring safe and beautiful toys to market at competitive prices.

Our Products

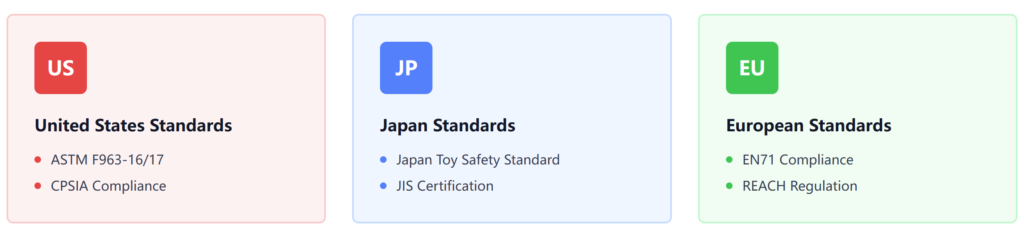

Global Safety Standards Compliance

At WoddlonToy, We ensure 100% compliance with international toy safety regulations in structure, material, surface coating, labeling & packaging

Safety-First Wooden Toy Manufacturing Process

1.Structure Design & Testing

Rigorous structural integrity testing to prevent choking hazards and ensure durability

2.Premium Material Selection

Only certified non-toxic wood materials that meet international safety standards

3.Safe Surface Coating

Lead-free, non-toxic paints and finishes that exceed global safety requirements

4.Compliant Labeling & Packaging

Proper age warnings, safety instructions, and packaging that meets all regulations

Complete wooden toy manufacturing solutions tailored to your brand and market needs

Professional color matching using official PANTONE standards ensures brand consistency across all products.

Role Play Toys

Puzzle Games

Building Blocks

Educational Toys

OEM Wooden Toy Manufacturing Steps

At WoddlonToy, we provide a clear and professional process to help new customers bring their wooden toy ideas to life. Whether you want to select from our catalog or create something unique, we are here to support you at every step.

1.Design & Concept

Choose from our E-Catalog: Browse our wide range of classic and modern wooden toys.

Custom Design Service: Share your ideas, sketches, or market trends with us, and our experienced design team will develop new toy concepts tailored to your brand.

OEM & ODM Options: We offer flexible solutions whether you need private labeling or fully customized toys.

2.Sample Development

After confirming design details, we prepare samples.

Sample cost and lead time are discussed and agreed upon in advance.

Our craftsmanship ensures prototypes reflect the final production quality.

3.Safety & Local Physical Testing

All samples undergo strict testing before shipping to you.

We follow international safety standards such as ASTM F963, EN71, CE, ensuring toys are safe for children.

We also recommend third-party laboratory testing if required by your market.

What Is Our Added Value To OEM Your Toy?

Professional anti-drop & durability tests to ensure toy quality.

Clear communication from design to delivery.

Flexible MOQs to support both startups and large distributors.

With WoddlonToy, you can turn your toy ideas into safe, beautiful, and market-ready wooden toys.

What's The Types of Wood for Manufacturing Wooden Toys ?

1.Pine Wood

Lightweight and affordable

Good for large toys (e.g., advent calendars, block sets)

Smooth surface, easy to paint or varnish

2.Basswood (Linden Wood)

Soft, fine texture

Excellent for detailed carving and painting

Higher cost compared to pine

3.Beech Wood

Hard and durable

Smooth grain, ideal for baby toys and blocks

Mid-range cost

4.Birch Plywood

Strong, stable, and cost-effective

Great for toy backboards, puzzles, and structural parts

Can be combined with solid wood

5.Rubberwood (Eco-friendly Option)

By-product of latex production (sustainable choice)

Hard, durable, widely used for export toys

Affordable compared to beech

6.Maple Wood

Very strong and durable

Used for premium toys and heirloom-quality pieces

Higher cost

What's The Finished Options For Manufacturing Customized Wooden Toy?

Clear Varnish (Roll coating vs Spray coating):

Roll coating saves cost (approx. $1.43 less than spray).

Spray gives a more even finish but costs more.

Non-toxic Paints / Water-based Coatings:

Safe for children

Bright colors, used for decorative toys

Natural Wood Finish:

Keep the original wood grain

Popular for eco-friendly and Montessori-style toys

What'sThe Common Packaging Materials For OEM Projects?

Color Box with Lamination – Premium look, good for retail shelves

White Box – Simple, cost-saving option

Brown Kraft Box – Eco-friendly, rustic style, often used for export

7 Ways To Make Wooden Toy Cost Less

For seasonal toys (like Christmas advent calendars), start development 6–8 months in advance. Delays in sampling and testing often lead to costly rush shipping or missed sales windows.

1. Shipping & Logistics

Use sea freight (25–45 days) instead of air express for bulk orders.

For urgent orders, use fast vessel service (shorter than standard sea freight, cheaper than air).

Consolidate shipments to reduce per-unit freight costs.

2.Sample & Testing Strategy

Plan design changes early to avoid multiple rounds of costly samples.

Use UV printing for sample stage, and only apply heat transfer printing after design confirmation.

Share vector artwork instead of hand drawings for clearer, cheaper printing.

3.Order Quantity Planning

Larger orders reduce the per-unit cost due to economies of scale.

Avoid very small batches — setup and testing costs get divided across fewer units, making each piece more expensive.

4.Material Choice

Change basswood plywood to poplar plywood — a cost-effective alternative that still meets safety standards.Upon agreement of fees and timelines, we’ll swiftly prepare samples for your evaluation. These samples will showcase the quality and craftsmanship of our wooden toys, ensuring they meet your standards.

5.Measurement Optimization

Adjust the toy size to be smaller, reducing wood usage and saving material costs without affecting play value.

6.Painting Process

Choose roll coating clear varnish instead of spray — saves about $1.43 per toy.

Limit multi-color painting; use 1–2 solid colors or natural finishes.

Avoid full-surface printing — focus on small logos or selective areas.

7.Packaging Options

Switch from full-color printed boxes to white boxes or kraft boxes.

Use stickers/labels instead of expensive 4C printed packaging.

For wholesale, consider bulk packaging (multiple toys in one carton).

Custom Wooden Toy FAQ – WoddlonToy

1. Can we add our logo on toys and packages?

Yes, we can customize toys and packaging with your logo, brand name, or design using printing, engraving, or stickers.

2. Can you do Ready-to-Ship products?

Yes, we can provide ready-to-ship wooden toys with neutral or simple packaging. Faster delivery, but less customization.

3. What are the main materials of wooden toys?

Pine wood (economical)

Basswood / Linden (smooth, easy painting)

Beech wood (durable, premium)

Poplar plywood (cost-effective)

Birch plywood (strong and stable)

All are eco-friendly and compliant with EN71 / ASTM F963.

4. How many ways are there to package toys?

Options include:

Color box (full printing)

Brown box with single-color print

White box

Window/display box

Customized retail package

5. Do you offer free samples? What is the delivery time?

Customer has to pay sample fee. Lead time 7–15 days. Express shipping 3–7 days.

6. What is the mass production delivery time?

35–55 days, depending on design and quantity.

Shipping:

Sea freight: 25–45 days

Fast vessel: quicker but higher cost

Air courier: 5–10 days

7. What payment methods do you support?

T/T, PayPal, Western Union, Alibaba Trade Assurance.

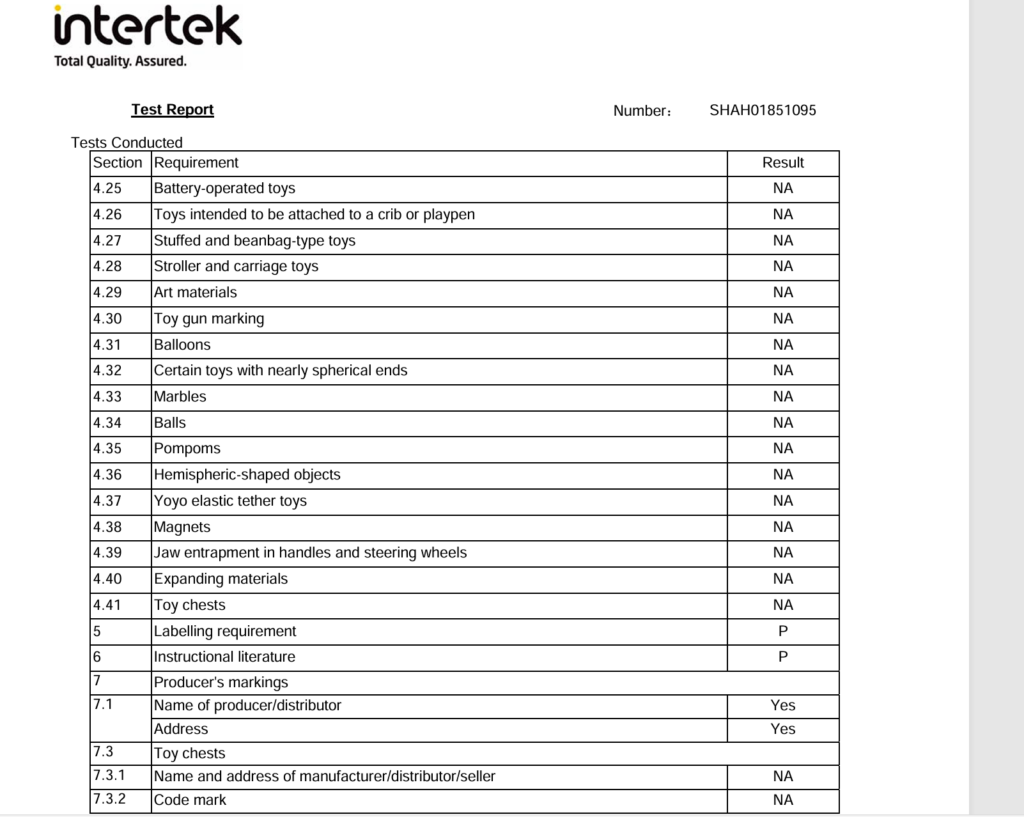

8. How to do toy testing? I’m a novice importer.

We guide you through testing with Intertek, SGS, TUV.

Standards: ASTM F963, CPSIA, EN71.

Covers safety, chemicals, flammability, and age grading.

9. What certificates do you have?

We can provide EN71, ASTM F963, CPSIA, CE test reports from third-party labs for most toys.

10. Can you help with product design?

Yes! You can choose from our E-catalog or let our designers create new toys based on your idea, sketch, or sample.

11. What is your Minimum Order Quantity (MOQ)?

Standard MOQ: 1,000 sets.

Better pricing at 3,000–5,000 sets due to bulk production.

12. Do you accept small trial orders?

Yes, we welcome small trial orders for new customers to test the market first.

13. Can you make eco-friendly or FSC-certified toys?

Yes, we can source FSC-certified wood and use water-based paints to make eco-friendly products.

14. Can you help with package design?

Yes. If you provide your artwork or brand guideline, we can prepare custom packaging design files for confirmation.

15. How do you control toy quality?

Incoming material inspection

In-process checks (size, painting, printing)

Drop test, soak test, tensile test, torsion test, impact test

Final random inspection before shipment

16. What safety standards do you follow for paints?

We only use EN71-3 / CPSIA compliant water-based paints. No harmful chemicals.

17. Can you provide exclusive designs?

Yes, we can sign NDA agreements and produce toys exclusively for your brand.

18. What if I need urgent delivery?

We can arrange priority production and ship by air or fast vessel. Extra cost applies, but you’ll save time.

Tip for new buyers: Developing a wooden toy project requires time for design, sampling, testing, and production. Please plan early, especially for seasonal products (Christmas, Easter, Back-to-School).

Why choose Us As Wooden Toy Manufacturing Company?

100% Compliant

Meet all global safety standards.

Premium Quality

Only the finest wood materials and craftsmanship.

Fast Delivery

Efficient production and shipping worldwide.

Custom Solutions

Tailored manufacturing to your specifications.

Customer Testimonial